Architectural materials have been evolving throughout history to satisfy human needs and desires. One way in which iron has evolved is when it became steel and emerged the era of steel structures. This one transformation may have, more than any other, changed the face of architecture and the whole world for good. What used to be mere fantasies on paper of structures with soaring heights and long spans floating on thin air are no longer dreams.

These long-span structures with awesome roofs are now a reality. So, what is the story of this revolutionary material? Who invented it? How is it manufactured? And what makes it special? Here, we will find out all about Steel Structures and more, when we review some of its most prominent architectural creations.

Read more:

- Sports Hall Roof Structure ‘Fluid Steel’ | Power Architecture

- 10 Extraordinary Neofuturistic Bridge Designs!

Who invented steel?

This is not a question we can answer in one word or a name. It is most likely blacksmiths were the earliest to discover that adding carbon to iron ore while smelting it in coal furnaces makes it stronger.

As to when and where steel can be traced back to 4000 years ago when it was used by warriors of the Roman Empire. It can, also, be traced back to BC India, to 3rd century China, and to 11th centuries Syria and the middle east. Up until the 18th century, steel was merely used for tools, weapons, and armors, because it was hard and expensive to make. However, with the invention of steam engines in the very same century, the industry of this iron alloy took a significant turn.

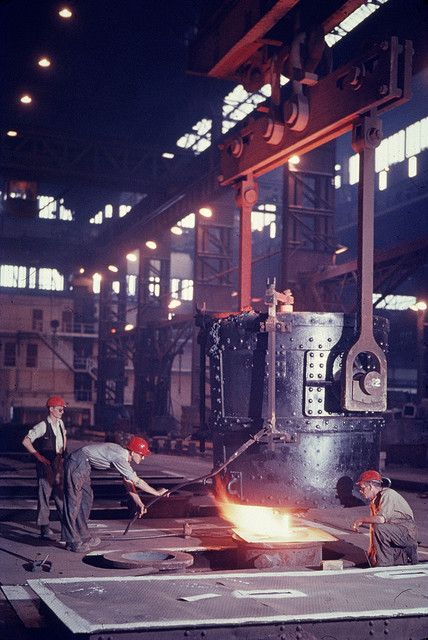

European engineers and inventors started working on methods to mass-produce steel. In 1855, English engineer Henry Bessemer introduced, for the first time, an inexpensive technique to produce steel, and it was named the Bessemer process. Ten years later, Carl Wilhelm Siemens and engineer Pierre-Émile Martin developed the open hearth furnace which yields a sufficient amount of heat to produce much larger masses of steel.

The 1880s have witnessed the rise of multiple iconic steel structures. The construction of Brooklyn Bridge, the world’s first steel suspension bridge, was finished in 1883. Two years later, the world’s first steel skyscraper, the Home Insurance Building in Chicago was completed. The very same decade, also, witnessed the rise of the world-famous Parisian landmark, the Eiffel Tower, in 1887.

How is steel manufactured?

Steel mainly comprises Iron with a percentage that amounts to 96%. The iron ore is extracted from the ground, the smelted (heated and melted) to get rid of impurities. Then, carbon is added with a percentage that normally ranges between 0.1-0.25%. Iron could also be alloyed with other elements like Manganese, Nickel, or Chromium to enhance the strength of steel.

What are the different types of steel?

Steel is sorted into four types, based on its components. These four types are:

1. Carbon Steel

Carbon Steel makes up 90% of the total amount of steel produced, and it can be classified into three categories: Low Carbon Steel, Mild Carbon Steel, and High Carbon Steel. The percentage of Carbon in low carbon steel does not exceed 0.3%, while the amount of carbon in High Carbon Steel could reach up to 1.5%. Mild Carbon Steel contains a percentage of Carbon between 0.3% and 0.6%.

2. Alloy Steel

Alloy Steel includes alloying elements like Manganese, Chromium, Vanadium, copper, or aluminum, besides iron. These elements vary in proportions to give steel particularly desired characteristics, like high strength, weldability, or resistance to corrosion.

3. Stainless Steel

Stainless Steel features Chromium as its main alloying element. It contains 10-20% Chromium which makes it exceptionally superior to mild steel as a corrosion-resistant material. It can be categorized into three groups based on its crystalline structure: Austenitic steel, Ferritic steel, and Martensitic steel.

4. Tool Steel

Tool steel is used to manufacture cutting and drilling equipment. It is characterized by its durability and high resistance to heat, owing to its composition which includes cobalt, molybdenum, tungsten, and vanadium, in different quantities.

What are the advantages of Steel?

Steel has many desirable characteristics which make it suitable for a wide range of applications, and here is why it has gained popularity in the fields of architecture and construction.

- Steel has high strength, and, accordingly, steel structures weigh less than typical structures.

- It is ductile; it can be bent, cut, and made into different shapes, and it does not buckle under pressure.

- It is highly durable, with a longer lifespan than other construction materials, and so it requires less maintenance.

- It can be recycled on a large scale which makes it a sustainable construction material.

- It is prefabricated, so it requires less construction time.

- Its properties are controllable and predictable, unlike concrete.

- Steel itself is more expensive than other construction materials, but all of the previous advantages make it more of an economic choice in the long run.

- Stainless steel is corrosion and fire-resistant as well as aesthetically pleasing.

Where do we use steel structures?

Steel has introduced a wide range of possibilities to the field of architecture. The under-construction Jeddah Tower is planned to reach a total height of 1Km. That would have never been possible if not for steel.

Skyscrapers are mostly constructed from steel. Their structure systems comprise steel beams, frames, and trusses, as well as elevator shafts from steel-reinforced concrete. The world’s current tallest buildings, Burj Khalifa is built from steel-reinforced concrete, and its 200-meter-high spire is constructed from structural steel. Its total height amounts to 830m.

-

Long Spans

Steel has also made it possible to build massive interiors, with long clear spans. These interiors are supported by steel frames, trusses, and space trusses.

The world’s current longest clear span belongs to Dallas Cowboys Stadium in the US. The stadium features two colossal arches, rising 292 feet (90m) high above the ground and spanning 1,225 feet (373m) in length. Both are connected by a single retractable roof, covering a total area of 73 acres (295,421m2).

-

Cantilevers

Cantilevers, made of concrete, could not extend for more than 1.5-2m without buckling. But now, steel and steel-reinforced concrete cantilevers can extend to 40 times that length. The world’s current longest cantilever is 85 meters long. It is part of South Korea’s Busan Cinema Center’s gigantic roof which has a total length of 163 meters and a width of 60 meters.

-

Finishings

Stainless steel is popular as an elegant and futuristic cladding material. It is, also, used as a framing material for doors and windows. Diane Dufresne Art Centre, in Canada, showcases steel as a finishing material. It is supported by steel-clad straight and inclined columns. The panels reflect the hues of the surrounding nature, giving a quite dramatic effect.