Are you looking for a convenient floor cover, elegant appearance, low maintenance, and functional? Then polished concrete may be just what you need! Polished concrete is not a new “fad”; it’s been discovered and used widely for over 17 years! Many of us have walked across those smooth, elegant surfaces or seen interior images where polished concrete is used. Consequently, it is no surprise that many users resort to the material as a sustainable and low-maintenance flooring option in every market segment.

The polished concrete industry is fast growing. It is even outpacing consumers and contractors with new technologies and methods. Hence, with the industry’s somewhat volatile state, consumers are bound to be confused about how polished concrete should be and what should be expected regarding its performance.

What is Polished Concrete?

Polished concrete is a flooring placement method that uses the preexisting concrete slab to make a challenging and aesthetically pleasing final product. Concrete polishing was first created for business installations but has now spread to dwellings, shopping centers, and business sectors.

The concrete is ground with finer diamond sharpeners to achieve a polished concrete finish. The concrete surfaces emerge from this technique feeling and wearing similarly to those of polished natural stone, like a granite countertop.

But how does polished concrete get its look? Yes, this doesn’t just happen haphazardly; a mix of aggregates, quartz, and colors creates a sophisticated industrial sense in spaces. Add to that the many processes it undergoes to get its textured yet smooth look.

How to Get the Best Appearance and Performance out of Polished Concrete?

First, you must know the types and processes required to implement polished concrete floors. Fortunately, we have gathered everything you need to know about this trending material, so let’s begin.

Let’s start by defining the term. According to the Concrete Polishing Association of America (CPAA), polished concrete is modifying the surface of exposed-aggregate or unsealed concrete floors to obtain a glossy appearance. Reading this, we can make out that there are many different variables to getting the desired material. Therefore, it is no surprise that different types of polished concrete exist. Here are a few:

-

Bonded abrasive polished concrete:

This type results from the mechanical processing, cutting, and refining of the concrete floor surface with bonded abrasive grains and fillers to achieve the desired level of aggregate exposure and glossy finish. It should be noted that bonded abrasive polished concrete is the most common version of polished concrete, even though its process is the most complicated. The installer must understand the concrete and equipment, such as the diamond tooling used in the process.

-

Burnished polished concrete:

This is achieved by rubbing abrasive pads against the concrete surface until the finish attains the desired level of glossiness.

-

Topical polished concrete:

The liquid coating is applied to the concrete floor surface for a glossy finish.

Yes, in most cases, all these types of floorings may look alike given their common feature; the “glossy finish.” Yet, it should be known that each type performs quite differently. This leaves users wondering which type would be most convenient for their needs. Consequently, users must become aware of the material processes and can understand and evaluate them.

Can any Concrete be Polished?

Before getting into details, let’s briefly discuss the material’s history. Polished concrete was initially used for industrial and manufacturing facilities in the late 1990s and 2000s. That was because there was no appropriate way to color the concrete. And even though there was the “acid stain” coloring process, it didn’t work well with polished concrete.

However, the invention of the concrete dye was a game-changer. It transformed what was once an industrial finish into a colored and decorative finish, valid for use in architecture and interiors. But even then, stain protection options were unavailable; the only treatment available was the densifier. However, that wasn’t a bad option; the densifier did harden the finish and created a much more long-lasting floor. It also assisted in withholding more color in the concrete.

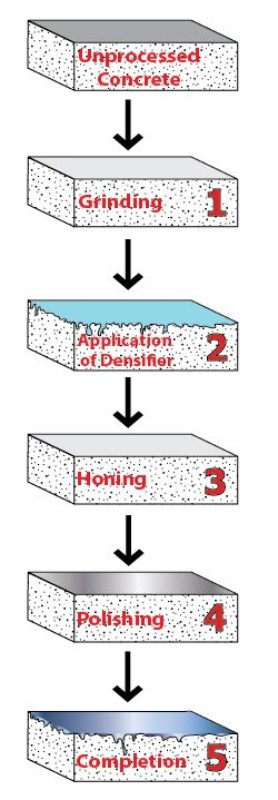

Understanding the process, how is Polished Concrete made nowadays?

We have already established that there are several variables of polished concrete, which means that each one requires an alteration in its making process. However, to make it simple, this is the most basic process of making polished concrete:

1) The concrete substrate in question must be rigid and flat. In more technical terms, the mix design should ideally be 4000 lbs to minimize admixtures. Also, it should be finished to a minimum of 50-floor flatness (FF). This may be achieved using a 12-inch “highway screed,” which locates and removes high and low spots from the concrete substrate during the finishing process.

2) Next is the polishing process, which can be divided into three sections: grinding, honing, and polishing. In each phase, a particular grit sequence is designed. This gives polishing technicians a chance to evaluate the performance of the overall process. Moreover, it eliminates any disappointments in the final steps of the process in case the overall look doesn’t meet the initial expectations. This way, the technician and client can observe the transformation of the flooring’s clarity, sheen, and aggregate levels throughout the process, allowing them to make any necessary alterations whenever needed.

A mock-up is usually made first to ensure that the polishing technician, architect, general contractor, and customer expect the same outcome. The mock-up also sheds light on the required technical process and ensures that the quality of the final product is up to the required standards.

Why Polished Concrete?

After reading all that, given its processing complexity, you probably wonder why you should choose polished concrete flooring. Here are some points to consider:

- The life cycle and maintenance of polished concrete

This is one of the main selling points of polished concrete. Having a smooth, hard surface, polished concrete is easy to clean using “polishing pads.” In addition to that, the material is durable and difficult to damage. And in case you are wondering how cracks are dealt with (as concrete is prone to cracking), patching materials are used to disguise them.

- Polished concrete, a “green” material?

Using the existing floor slab with some treatment, polished concrete can be considered sustainable. Additionally, the slabs have a high thermal mass which can effectively retain heat in winter. Yet, we should not forget the high carbon footprint associated with concrete and its production.

- Versatility

Remember how hard it was to color polished concrete in the past? This is no longer the case! The material has become highly customizable thanks to the wide variety of finishes, aggregates, and cement colors in the concrete itself. Moreover, the finishing can mimic various materials, including stone and ceramic tiles, but with the added benefits of polished concrete.

Before the slab is placed, the colors are usually mixed into the concrete. However, this may also be done by applying dye, stain, or waterproof paint later. Furthermore, the surface of the concrete may be carved with patterns while it sets, giving it a “faux tile” effect.

Polished Concrete Examples

Although it is mainly used for interior flooring, designers have been pushing its limit for years. The material may be used for countertops, feature walls, patio floors, and large exterior panels. Want to see how? Check out these projects:

1) 105JON Renovation of a House Between Dividing Walls | Vallribera Arquitectes

A couple in Barcelona makes the bold move of abandoning the city. They’ve come to terms with the fact that they can’t afford a house in the capital with a yard. They were able to tailor the project to their specifications in the Vallès. They decide on a residence. Basically, it’s just a rowhouse with no upper stories.

A polished exposed concrete floor gave the house thermal persistence and made the space more pleasant to spend time in. The old roof’s framework and party walls are made of exposed brick stand in contrast to the newly installed polished concrete floor on the lower floor and rubber linoleum flooring on the first floor.

2) Church of the Holy Spirit in Pegognaga | LR-Architetti

The new Holy Spirit Church in Pegognaga, close to Mantua, is built on a plot of land through which the hall’s gabled bulk rises. Everyone is welcome to use the church hall at no cost. Slim, terracotta-colored concrete columns support the ceiling and flank the perimeter, which features tall windows. The interior is delineated by two parallel rows of hanging tubing light fittings. The outer sidewalk and the hall floor are both made of the same pinkish Lessinia stone, which is rough in the entrance court and has polished concrete glossiness inside.

Also Read: South Korean Churches: 10 Flawless Cathedrals Worth Seeing for Their Excellence.

- ©Marco Introini

- ©Marco Introini

- ©Marco Introini

3) Concrete 0023 | studio eight twentythree

A Mumbai-based fabric design and production company has a permanent gallery space called “Concrete 0023.” The studio’s current focus is on designing and researching things and environments with concrete as the principal material in preparation for the exhibition and introduction of a new fabric collection by a Mumbai-based manufacturing and design firm. Walls are experimented with by polished concrete on their surfaces in differing degrees of mixtures, resulting in visually distinct characters; the unpredictability of the ultimate result adds to the appeal.

- ©studio eight twentythree

- ©studio eight twentythree

- ©studio eight twentythree

4) Apple Tree House | ACDF Architecture

5) Barfold Estate | LAYAN

6) The Wolf House | Wolf Architects

©Dave Keluza

A sizable, gated yard faces north in front of the house, making it an ideal spot for kids to play in safety. It opens onto a spacious double-height front porch, from which you can enter the dwelling. Thanks to the dark polished concrete surface, the front porch features a large blackboard for the kids to use.

- ©Dave Keluza

- ©Dave Keluza

- ©Dave Keluza

7) T Square Coworking Space | Stateline No. 7 Architects

8) Kristalia New Headquarters | Sandro Burigana

© Paolo Contratti

Kristalia is an industrial renovation for a firm that makes glass ornaments and other small items. It’s all a matter of green (trees and hills), white (snow and brightness), black (dark vs. artificial lighting), fresh air, and authenticity so that even constructed materials like polished cement can fit in with their natural scenery that was always a part of Kristalia.

- © Paolo Contratti

- © Paolo Contratti

- © Paolo Contratti

- ©Craftsman Concrete Floors

- ©Pats Color

- ©Cristiano Bauce

- ©Smooth Concrete

- ©Craftsman Concrete Floors

- ©Glossy Floors

- ©concreteartfx.com

- ©studio eight twentythree

- ©studio eight twentythree

- ©studio eight twentythree

- ©studio eight twentythree

- ©Dave Keluza

- ©Dave Keluza

- ©Dave Keluza

- © Dave Keluza

- © Paolo Contratti

- © Paolo Contratti

- © Paolo Contratti

- © Paolo Contratti

- ©José Hevia

- ©José Hevia

- ©José Hevia

- ©José Hevia

- ©Marco Introini

- ©Marco Introini

- ©Marco Introini

- ©Marco Introini

- ©Adrien Williams

- ©Adrien Williams

- ©Adrien Williams

- ©Adrien Williams

- ©Victor Vieaux

- ©Victor Vieaux

- ©Victor Vieaux

- ©Victor Vieaux

- ©Lee Chamberlain Photographer and Ben Winckler Photography

- ©Lee Chamberlain Photographer and Ben Winckler Photography

- ©Lee Chamberlain Photographer and Ben Winckler Photography

- ©Lee Chamberlain Photographer and Ben Winckler Photography