It is remarkable that technology has a significant effect on our lives, and it influences all disciplines and majors including architecture. Information technology has facilitated the work of architects and provided them with software and applications that saved a lot of their time and effort – on the top of these is the BIM workflow. Even though there is the extreme influence of technology on architecture, it has the lowest productivity among other fields[1]; it was approved by the U.S. Department of Commerce and the Bureau of Labor Statistics that architecture recently has less production than it had in the ’60s [2].

This decay backs to several reasons:

- The wasted time in documentation and paperwork, which increased with the design’s complexity.

- The dependency on human hand force in the construction process. Moreover,

- The poor communication between design teams and contractors.

Other industries build upon machinery also rely widely on Robots, and the automotive industry is setting a good example. The main cause of this is that such industries produce mass products, and their manufacturing process depends on repetition.1 On the contrary, architectural design hangs on the uniqueness in identity and components.

Even so, the concept of involving robots in the construction process is becoming the prime consideration and concern of AEC firms, especially the firms that adopted BIM technology to their system. Robotic arms help create entire buildings and pavilions! They believe that robots can advance their productivity and accelerate the design workflow. In this article, we will argue the consequences of using robots in construction, and its effects on the BIM workflow.

How Robots can improve BIM WORKFLOW?

How can robotization accelerate the design process based on BIM technology? As we know, BIM has notable benefits on the design process; it simplified the tasks of architects and engineers, their performance becoming perfectly in the tune; it speeded up the data exchange process and smoothed the collaboration between different disciplines, it saved time and efforts, it reduced the documents and official papers and it improved the review and modification cycle. All this is excellent and perfect! Nevertheless, the stumble occurs in the construction process with the imperfect communication with the contractors. The accuracy of the BIM model will not be precisely built. Why? Because of the reliance on hand-operations. No matter how skillful the craftsmen are, the errors will be available. These technical mistakes, regardless of the structure’s simplicity, will have an impact on the workflow.2 For example, if the column was planted few centimeters off position, the coordinates of beams and other structural elements should be revised and repositioned. In that case, the contractor sends a technical report to the project manager describing the errors, who in turn will ask for an immediate meeting with the design teams for an urgent solution.2 The team decides whether to recast the column or modifying the whole design in line with the error. Both solutions are a total waste of time, which leads to delays in the project time schedule and to extra costs and charges.

Thus, the dilemma lies in the lack of integration between BIM and contractors. The prefabricated structural elements can be installed wrongly if the old construction methods were used. Therefore, technology should be involved effectively to transfer the technical data of the models accurately. How? By employing the Robots. As mentioned before, robots are utilized in most industries, which increased productivity and efficiency. Why don’t robots be operated for architecture? It will definitely have great benefits on the construction process; first, robots reduce errors and the rework. They double the precision of installation, and build the model meticulously and implement it literally. Secondly, they save time and achieve an efficient timetable. Thirdly, they manage the construction process and slash the number of waste materials.1 Finally, robots will be able to produce complex geometries and shapes that might have been impossible to construct before.[3]

Examples of using ROBOTS with BIM Technology

Recently, BIM Companies and known construction firms are carrying out projects and researches that apply robotization for BIM in the construction process. The projects are real, well implemented, and promising.

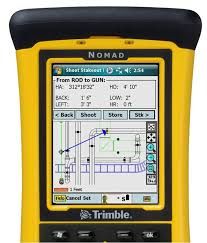

1. Tekla Structures/LM80 Handheld Software Integration

Tekla Structure BIM had collaborated with Trimble Robotic Total Solution in developing software that eases the interoperability between the two technologies. Trimble LM80 software is able to transfer the data accurately from Tekla Structure Layout Manager to Trimble Robotic Stations. It simply set up the coordinates of structural elements on the site. Swinerton Builder is the first firm that employed this software in their Waikiki Plaza Expansion project in Honolulu. ” With this connection, we are able to deliver precise well-coordinated information to the field. Prior to the integration between Tekla Structures and the Trimble LM80 software, much of our time was spent in the office developing adequate dimension schemes with back checks.

“The Project Manager Doug Paasch at Swinerton described the company’s experience with the software. The company also used this technology in a college campus renovation project located 60 miles from Sacramento. The Superintended and Detailer Jeremey Melton illustrated the process: ” Better yet, once the foundation or other site work is complete, we can quickly resurvey the site to gather the actual bolt locations and other data from the field and transfer it back to the original 3D model to create as-built drawings, map out the floor wall locations, and other items and create drawings.”[4]

2. Scanner MOBILE Robots for BIM

The concept of Mobile Robots was implemented first in the ’40s, and today they are commonly used in commercial and industrial fields. They are movable machines; some can talk, walk, clean, and take pictures, etc. For architecture, they were never used for design or construction before, in spite of their numerous benefits and advantages. Nowadays, mobile robots are developed to serve architectural purposes, especially with BIM technology. They are equipped with a Wi-Fi connection, a Local Positioning System (LPS), and digital cameras. The LPS technology makes it possible for robots to scan the building horizontally with up to 1,000 sq per minute, and vertically to reach 4 feet height. This information can be useful for the design process, and it can be sent wirelessly to the design team with coordinates, temperature, radiation, and even air quality. The technology is also profitable for future maintenance schemes, which can take photos and videos that viewing the latest condition of the building.[5]

3. Skanska integrates Robots with BIM

The Swedish construction firm Skanska has adopted BIM technology a long time ago and employed it effectively in all its projects. In addition, it involved the robot technology in its construction process with interoperability with BIM software. In their Norway office, they used drilling robots that derive their accuracy from the BIM model. “On a recent test during construction of Skanska Norway’s new head office, a drilling robot mounted on a mobile elevated work platform performed two and a half times faster than a comparable two-person crew doing the same work via traditional means,” BIM Manager, Rubert Hanna explained. In Sweden, the firm applied robots for bending and welding the rebars that are used for pile fabrication. The district manager of Skanska Sweden described: “We purchased our first robot for this application in the 1990s, and this year the robots will enable this facility to produce 175,000 meters of concrete piles,”[6] In their U.S office, they participated in research that studied the possibility of using Robotic Total Station for measurement and obtaining global coordinates. Students from Texas A&M University and College Station prepared the research, and it has the same concept as the Trimble Software that was employed by Tekla Structure. The difference here is that they used Image Assisted Stations (IATS) that were provided with cameras.[7]

Robot Technology can be used for BIM

1. Quadcopters

Gramazio Kohler Research had several studies about using quadcopters for the construction process. They have an experiment of using those flying machines successfully in assembling a 6-meter height model of a twisting tower with 1500 foam bricks. The quadcopters pick the brick and receive the exact coordinates from a motion capture system that is mounted in the ceiling of the room.[8] The installation speed ranges about 100 bricks per hour and can be used to implant Space frame structure’s elements which can be placed easily even for high altitude. Moreover, quadcopters can be employed for tensile structures in terms of carrying and tightening the cables.[9] The quadcopters will be a construction revolution for its significant outcomes.

2. Robots for Concrete, Steel, and Polymer 3D Printing

The Chinese company Winsun has been able to build full houses with concrete and other recycled materials using a huge 3D printer. The company clarified that the project was successful in saving 60% of construction materials, 70% of the estimated time, and 80% of the labor.

Joris Laarman had designed, in collaboration with MX3D a steel printer that is used to print an entire bridge at the MX3D for Oudezijds Achterburgwal canal. The printing process started in 2015 and it is expected to be done in 2017! 10

Polymer Printers were first established in 2007 by the Professorship for Architecture and Digital Fabrication at ETH Zurich. In the beginning, off-shelve polyurethane (PU) foam was used as a printing material. It was printed layer by layer and hardened by heat with 30 cm per minute speed. This polymer printer is convenient and can be occupied to produce the doubly curved meshes and to construct extreme cantilevers as a porous material.1

Written by Arch2O Internship Team

[1] Hack, Norman, Willi Lauer, Silke Langenberg, Fabio Gramazio, Matthias Kohler. “Overcoming Repetition: Robotic fabrication processes at a large scale.” International journal of architectural computing 3, 11 (2013): 285-99 http://gramaziokohler.arch.ethz.ch/web/publikationen/e/papers/0/0/0.html- [2] Whaley, Mike. “How BIM, Robotics And 3-D Printing Will Improve Efficiencies On The Jobsite: Page 2 Of 2”. Construction Business Owner Magazine, August 2014 Issue. http://www.constructionbusinessowner.com/technology/project-management/august-2014-how-bim-robotics-and-3-d-printing-will-improve/page/0/1

- [3] Waibel, Markus. “Architects Using Robots To Build Beautiful Structures”. Spectrum.ieee.org. September, 2011. http://spectrum.ieee.org/automaton/robotics/industrial-robots/robots-in-architecture

- [4] Tekla. “Swinerton Pushes BIM To The Field: Connecting Building Information Models To Robotic Total Stations”. 2013. http://www.tekla.com/us/references/swinerton-pushes-bim-field-connecting-building-information-models-robotic-total-stations

- [5] Dietsch, Jeanne, and Stuart Rich. “Robots In Every Building? It’s Closer Than You Think.”. Automatedbuildings.com. February, 2009. http://www.automatedbuildings.com/news/feb09/articles/mobile/090125024654mobile.htm

- [6] Skanska – Global corporate website,. “Integrating Robots Into Construction”. January, 2016. http://group.skanska.com/media/articles/integrating-robots-into-construction/

- [7] Kang, Julian et al. “BIM To Field: Robotic Total Station And BIM For Quality Control.” London: eWork and eBusiness in Architecture, Engineering and Construction – Gudnason & Scherer (Eds), 2012. https://www.academia.edu/2922881/BIM_to_field_Robotic_total_station_and_BIM_for_quality_control

- [8] Augugliaro, Federico, Sergei Lupashin, Michael Hamer, Cason Male, Markus Hehn, Mark W. Mueller, Jan Willmann, Fabio Gramazio, Matthias Kohler, Raffaello D’Andrea. “The Flight Assembled Architecture Installation.” IEEE Control Systems Magazine 04, 34 Cooperative Control (2014): 46–64. http://gramaziokohler.arch.ethz.ch/web/publikationen/e/papers/0/0/0.html

- [9] Mirjan, Ammar, Fabio Gramazio, Matthias Kohler. “Building with Flying Robots.” In FABRICATE: Negotiating Design and Making, edited by Gramazio, Fabio, Matthias Kohler, Silke Langenberg, 266-71. Zürich: gta Verlag, 2014. . http://gramaziokohler.arch.ethz.ch/web/publikationen/e/papers/0/0/0.html

- [10] Zimmermann, Eva. “What The Future Holds For 3-D Printing In Architecture And Design”. Houzz. January, 2016. http://www.houzz.com/ideabooks/57915631/list/what-the-future-holds-for-3-d-printing-in-architecture-and-design

- robotization of BIM

- courtesy of © Joris Laarman for MX3D

- robotization of BIM

- photography by Olivier de Gruijter

- courtesy of © Joris Laarman for MX3D

- Trimble