An architect’s guide to effective design must include a deep understanding of the various wooden boards available in the market today. This guide explores the top 5 wooden boards every architect should know to create stunning designs that stand the test of time.

The Evolution of Wooden Boards

Wood has been in the limelight for years as one of the best building materials in the construction industry. It has received recognition as a durable, recyclable building material with a weaker carbon footprint and, therefore, a better potential as a green material.

Whether wood comes from reclaimed wood or pseudo-wood made from agricultural waste, this magical building material has excellent construction potential and endless innovative possibilities, all encouraging manufacturers and designers to dig deeper into it and improve the technologies that will use it to the max.

Now, the versatility of wood may overwhelm you and makes you wonder where to start and which type of wood would be best for your project. We are here to help you get the hang of it and provide you with this manual on wooden boards and how to use them.

The Types of Wooden Boards You Need to Know About

Not all wooden boards are the same. While some are brilliant for indoor use, they can deteriorate quickly if used outdoors. Let’s go over the five primary types of wooden boards you need to know about right now.

1) Medium Density Fiberboard (MDF)

Medium-density fiberboard is made of wood fibers and synthetic resin. The mixture is then compressed using pressure and heat, resulting in excellent, uniform boards that can be cut at any angle. After MDF is processed and cut into boards, the result is dense, solid wooden boards that can be used with different finishes to suit various design needs.

Although MDF is highly versatile and practical, it has downsides since it isn’t water-resistant, meaning that the wood can easily cling to moisture, causing the wooden part of the building to decay. Just because MDF can’t tolerate water well doesn’t affect its potential as a building material since MDF boards are very suitable for use in dryer environments. However, plenty of manufacturers produce fireproof, water-resistant MDF boards.

Also Read: The Only Three Types of Wood That Every Architect Should Be Aware Of

You can find MDF boards used in walls or door claddings, but undoubtedly MDF boards are the most used material for carpentry since furniture isn’t usually exposed to moisture. MDF boards can be cut in any shape, so many manufacturers opt for them in various finishes, such as melamine, lacquered paint, natural sheets, and pattern printing.

Another alternative to fiberboard is High-Density Fiberboard (HDF), which also consists of artificial resin and wood fibers. The difference between MDF and HDF is the manufacturing process; HDF is subjected to more heat and pressure, resulting in a more resistant material that can support more weight and offer great coverage for large extensions.

2) Eco-friendly MDF

Meet Wheat Board, also known as Ecoboard, is the new HDF alternative that’s 100% environmentally friendly. Ecoboards are the next generation of MDF fiberboard, made of 100% natural wheat straw instead of wood. The materials used for making Wheat Boards are agricultural leftovers from harvests.

These byproducts were usually discarded or burned, worsening the climate crisis. Instead of impacting the environment, manufacturers take the agricultural waste, which then goes through an advanced processing technology resulting in a material that’s way better than MDF and other particleboards.

Wheat Boards are formaldehyde-free wooden boards that, unlike MDF and HDF, which use artificial resin and wood fibers, combine the eco-friendly adhesive MDI with the wheat straw instead of other substances that impact the environment. The two materials react together and form a firm, irreversible chemical bond giving the Wheat Board a steady shape, deformation-resistance, a hard texture, and weight-bearing abilities.

Wheat Boards are moisture resistant due to the extensive amount of natural wax the material is finished with. The natural sealants and water-resistant coatings make Wheat Board a good choice for the roofs and walls of a design. Due to the amount of silicon dioxide in straw fiber, Wheat Boards have a natural fireproof quality without further additives or coatings.

Also Read: 10 Ideal Wooden Floor Layout Patterns Every Homeowner Should Be Familiar With

3) Medium Density Particleboard (Chipboard and MDP)

Medium-density particleboard (MDP) and chipboard are created by combining sawdust and other wood debris with artificial resin and glue and then pressing them together to build wooden boards. The thing about MDP and chipboard is that they’re pretty cheap compared to other varieties of wooden boards. Unlike MDF, the surface chipboard isn’t smooth in any way that would allow simple finishes and varnishes to be stuck on it. Manufacturers usually use special hardware and finishes to get a satisfactory result from the chipboard.

Although MDP and chipboard undergo the same manufacturing process, MDP boards consist of finer particles deposited on the board’s surface, and the larger particles are at its core. Due to the finer texture, some finishes and varnishes can be used with it.

MDP and chipboard don’t tolerate moisture well, may have some imperfections, and aren’t as strong as other varieties of wooden boards. They’re a great choice of material for making simple furniture, especially MDP since it’s adjustable and can be used with different claddings.

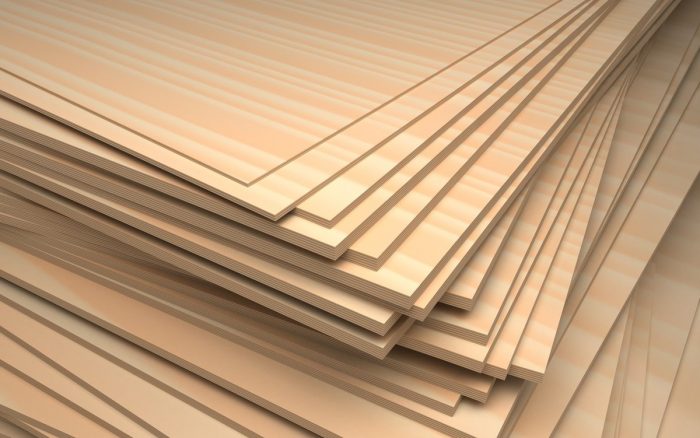

4) Plywood

Plywood is a different variety of wooden boards as it is made of overlapping wood sheets that are glued together perpendicularly and then heat pressed. The cross-directional fibers of plywood allow it to withstand more significant pressure than other types of wooden boards, such as particleboards such as MDP, and MDF.

On the one hand, particleboard consists of these glued together and heat-pressed particles; they’re not as strong as plywood, are less water-resistant, and are usually used for making furniture or doors. Conversely, plywood is quite strong and can be used for anything from furniture to ceilings, doors, etc. Unlike MDP and chipboard, plywood is compatible with all paints, finishes, varnishes, glue, melamine, and natural sheets.

5) Oriented Strand Board (OSB)

The last wooden board type we will discuss is the Oriented Strand Board, or OSB for short. OSB’s unique aesthetic makes it one of the ideal wooden boards for countless designers and architects. It can easily be integrated into many interior and architectural designs, not only due to its functionality but also because of its pleasant texture that gives the design a distinctive impression.

OSB is made of wood chips mixed with resin, then pressed in perpendicular layers, and then treated with extreme heat and pressure. OSB possesses outstanding rigidity and mechanical strength, which means they can withstand pressure and be used on a larger scale in construction.

OSB provides excellent insulation, unlike any other type of wooden board, due to its density and the fact that are no spaces inside the board. OSBs are very uniform and come with no knots or cracks, and because their surface is quite rough, it is virtually impossible to laminate or clad them in melamine. They can be coated in unique finishes and varnishes, however.

These ecological wooden boards are best for outdoor use since they are durable against rain, wind, humidity, and exposure. They can be taken apart and recycled as doors, ceilings, or floors, making them durable building materials that can be reused one time after another.

- ©Kaboompics

- ©Decorative Wall Panels

- ©Ultimate Jets

- ©Chemical Release Company Limited

- ©Wanhu Board

- ©Insulation UK