Insulation materials and systems are crucial for maintaining comfortable indoor temperatures and reducing energy consumption in buildings or structures. They act as a barrier against heat transfer, preventing the escape of warm air in the winter and the entry of hot air in the summer. Effective insulation helps create an energy-efficient environment and reduces heating and cooling costs. It also contributes to a quieter and more peaceful indoor atmosphere by reducing noise transmission. Insulation is essential for creating a comfortable and energy-efficient space.

Insulation Materials

here are some examples about Insulation materials.

Fiberglass:

Fiberglass is a widely used insulation material made of fine glass fibers. It is commonly found in various forms, such as blanket insulation, loose-fill insulation, rigid boards, and duct insulation. It is created by melting glass and spinning or blowing it into fibers. Many manufacturers incorporate 40% to 60% recycled glass into their products. Loose-fill insulation is typically applied using an insulation-blowing machine, either in open-blow scenarios like attics or closed-cavity applications such as existing walls or covered attic floors.

Mineral Wool Insulation Materials

Cellulose insulation is created from recycled paper products like newsprint, with a high recycled material content ranging from 82% to 85%. The paper is broken down into small pieces and transformed into fibers, resulting in a tightly packed product that can be used in various building cavities. It is commonly employed in both new and existing homes, either as loose-fill in open attic installations or as dense packed insulation in walls and cathedral ceilings.

In existing structures, installers typically remove a strip of exterior siding, drill three-inch holes into each stud bay, and insert a special filler tube to blow the insulation into the wall cavity. The insulation is usually blown to a density of 1.5 to 3.5 lb. per cubic foot. After installation, the holes are sealed with a plug and the siding is replaced and touched up if needed to match the wall.

In new construction, cellulose insulation can be applied in two ways: damp-sprayed or installed dry behind netting. Damp-sprayed cellulose involves adding a small amount of moisture at the spray nozzle tip, which activates starches in the product and helps it adhere inside the cavity. This type of cellulose insulation is usually ready for wall covering within 24 hours. Alternatively, cellulose can be blown dry into netting that is stapled over building cavities.

Cementitious Foam Insulation Material

Cementitious insulation material is a foam type used for insulation. It can be sprayed or placed in cavities. One specific type of cementitious foam called aircrete® contains magnesium silicate and has a consistency similar to shaving cream. Air krete® is pumped into closed cavities. Cementitious foam has similar costs to polyurethane foam, is non-toxic and non-flammable, and is made from minerals extracted from seawater, such as magnesium oxide.

Polystyrene Insulation Materials

Polystyrene, a clear and colorless thermoplastic, is often used to create foam board insulation, concrete block insulation, and loose-fill insulation made up of small polystyrene beads. Molded expanded polystyrene (MEPS) is commonly used for foam board insulation and is available in the form of small foam beads. These beads can be used for insulating concrete blocks or hollow wall cavities. However, they are very lightweight, prone to static electric charge, and challenging to manage.

Natural fibers like cotton, sheep’s wool, straw, and hemp are commonly utilized as insulation materials.

Straw bale construction, which was popular on the Great Plains of the United States 150 years ago, is gaining renewed interest. In the 1930s, a method of fusing straw into boards without adhesives was developed. These panels, typically 2 to 4 inches thick, are faced with heavyweight craft paper on both sides. They can also be used as sound-absorbing panels for interior partitions. Certain manufacturers have even created structural insulated panels by compressing multiple layers of straw panels.

Cotton

Cotton insulation is made up of 85% recycled cotton and 15% plastic fibers that have been treated with borate. This borate treatment acts as a flame retardant and repellent for insects and rodents, similar to cellulose insulation. One specific product utilizes recycled trim waste from blue jean manufacturing. This insulation product requires minimal energy for manufacturing due to its recycled content. It is available in batts.

To make it more concise: Sheep’s wool is treated with borate to resist pests, fire, and mold. It offers R-13 and R-19 values for 2 by 4-inch and 2 by 6-inch stud-framed walls, respectively.

Types of Insulation Systems

There are two main ways to insulate a structure: cavity insulation and continuous insulation.

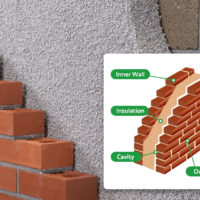

Cavity insulation

It is installed in the empty spaces between the studs in a wall, while continuous insulation is installed on the exterior of the wall. It is typically made of fiberglass, cellulose, or mineral wool. It is installed by blowing it into the cavities between the studs or by stuffing it into the cavities with a hand or a tool.

- © Next Energy

- © Next Energy

- © Next Energy

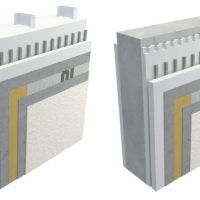

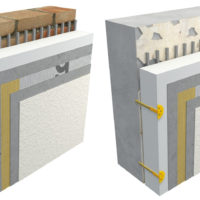

Continuous Insulation System

Continuous insulation (CI) is a layer of insulation that is installed on the outside of a building’s frame. It helps to reduce heat transfer between the building and the environment, which can save energy and money. CI is defined by ASHRAE 90.1 as “insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings.” The ASHRAE 90.1 Standard is a benchmark for commercial building energy codes in the U.S. and is used in many municipal building codes. It can be made from a variety of materials, including fiberglass, cellulose, and foam.

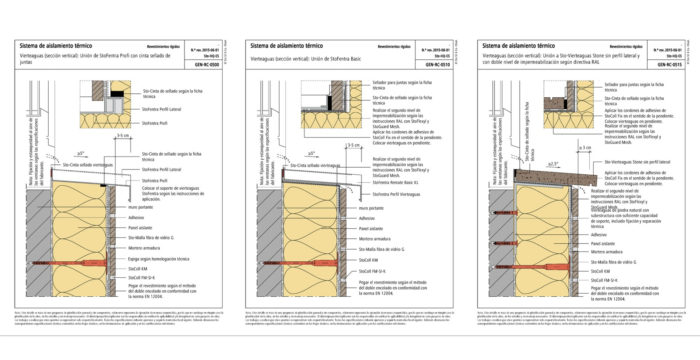

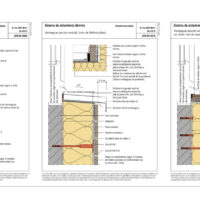

- © STO

- © STO

- © STO

CI is typically installed by blowing it into the cavities between the studs or by attaching it to the exterior of the wall. CI can also be sprayed onto the exterior of the wall. It is more effective at reducing heat loss than traditional insulation methods, such as batt insulation. This is because CI creates a continuous barrier that prevents heat from escaping the building. CI can also help to improve the soundproofing of a building. It is a cost-effective way to improve the energy efficiency of a building. It can save money on energy bills and reduce greenhouse gas emissions. CI is also a durable and long-lasting material that can last for many years.

Here are some of the benefits of CI:

1. Lightweight 100% FRP system (no metal to rust or react). CI is made from fiberglass-reinforced plastic (FRP), which is a lightweight and durable material. FRP is not susceptible to rust or corrosion, which makes it a good choice for use in harsh environments.

2. CI can be used to replace metal cladding attachment systems, which can be a source of heat loss. CI creates a continuous barrier that prevents heat from escaping the building.

3. Superior pullout strength and can be installed vertically or horizontally depending on construction requirements. CI has superior pullout strength, which means that it is less likely to be pulled out of the wall. CI can be installed vertically or horizontally, depending on the construction requirements.

4. Works with all non-proprietary insulation. CI can be used with all non-proprietary insulation, which gives the builder flexibility in choosing the type of insulation that is best for the project.

5. No in-field fabrication is required. CI is prefabricated, which means that there is no need for in-field fabrication. This can save time and money on the project.

6. Invisible in rainscreen cavities. CI is installed in the rainscreen cavity, which means that it is not visible from the outside of the building. This can improve the aesthetic appeal of the building.

7. Double fastening system on the front flange. CI has a double fastening system on the front flange, which provides additional security and prevents the insulation from being pulled out of the wall.

8. Code compliant. CI is code-compliant, which means that it meets the requirements of the building code. This can help to ensure that the building is safe and energy-efficient.

Types of Insulation

Blanket: Batt and Roll Insulation

Insulation Materials: Fiberglass, Mineral (rock or slag) wool, Plastic fibers, and Natural fibers

Where applicable: Unfinished walls, including foundation walls and Floors and ceilings

Installation methods: Fitted between studs, joists, and beams.

Advantages: Suited for standard stud and joist spacing that is relatively free from obstructions and Relatively inexpensive.

Concrete Block Insulation

Where applicable: Unfinished walls including foundation walls, New construction or major renovations and Walls (insulating concrete blocks).

Installation methods: Insulating concrete blocks are sometimes stacked without mortar (dry-stacked) and surface bonded.

Advantages: Insulating cores improve the R-value of walls. Insulating the exterior of a concrete block wall brings the mass inside the conditioned space, which helps regulate indoor temperatures. Autoclaved aerated concrete and autoclaved cellular concrete masonry units have ten times the insulation value of regular concrete.

Foam Board or Rigid Foam

Where applicable: Unfinished walls, including foundation walls, Floors and ceilings and Unvented low-slope roofs

Installation methods: To ensure fire safety for interior applications, it is necessary to cover them with 1/2-inch gypsum board or another material approved by building codes. On the other hand, exterior applications need to be covered with a weatherproof facing to protect them from the elements.

Advantages: Even though it is thin, outdoor shading systems have high insulating value. When installed continuously over frames or joists, it can effectively block thermal short circuits.

Insulating Concrete Forms

Where applicable: Unfinished walls, including foundation walls for new construction

Installation methods: The cores in the blocks are usually filled with concrete to create the structural part of the wall when installed as part of the building structure.

Advantages: providing strong resistance to heat transfer.

Where applicable: Enclosed existing wall or open new wall cavities, unfinished attic floors, and Other hard-to-reach places.

Installation methods: By blowing it into place with specialized equipment, and although it is not advised, it is occasionally poured in.

Advantages: Good for adding insulation to existing finished areas, irregularly shaped areas, and around obstructions.

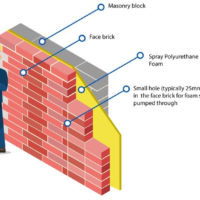

Sprayed-Foam and Foamed-In-Place Insulation

Insulation Materials: Cementitious, Phenolic, Polyurethane, and Polyisocyanurate

Where applicable: Enclosed existing wall, Open new wall cavities and Unfinished attic floors

Installation methods: It can be applied in two ways: either using small spray containers or in larger quantities as a pressure sprayed or foamed-in-place product.

Advantages: Great for enhancing insulation in already completed spaces, irregularly shaped spaces, and areas with obstacles.

- Image Courtesy of Banksphotos

- Image Courtesy of Paul Norton, NREL

- Image Courtesy of DonNichols

- Image Courtesy of soprema

- courtesy of service partners

- courtesy of Builder

- Image Courtesy of Aleksandar Karanov / Getty

- courtesy of Havelock Wool

- © Next Energy

- © Next Energy

- © Next Energy

- © STO

- © STO

- © STO

- Image Courtesy of STO

- Image Courtesy of STO