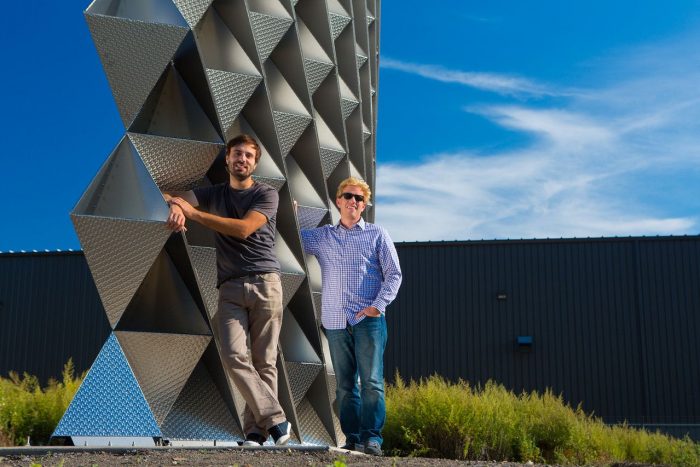

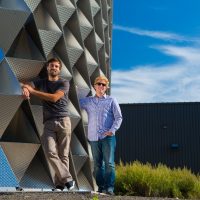

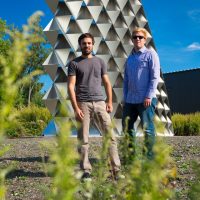

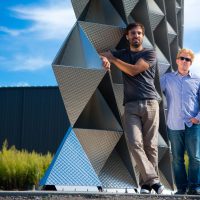

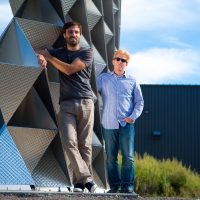

3xLP is Nicholas Bruscia and Christopher Romano’s iteration of an architectural screen which was awarded a first place in Tex-Fab’s digital fabrication competition, SKIN. Their winning entry of a structural, textured metal system is been given an opportunity to be developed into a facade by Zahner. The designers’ exploration of the relationship between academia and manufacturing merged at the University at Buffalo’s (UB) Department of Architecture where the team is based.

Tex-Fab’s co-director, Andrew Vrana praised the project for its innovative approach, which used parametric design and digital fabrication to reinforce their idea of collaboration. The entry was a third stage development which was initiated during the team’s research at UB with a digital model. The second stage of the project’s evolution was realized with the help of local manufacturer Rigidized Metals, (RM) who provided material knowledge for textured metal.

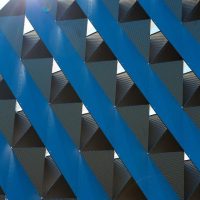

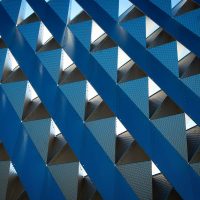

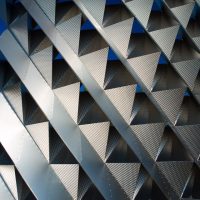

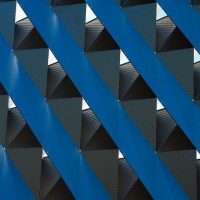

For the competition entry, the team adjusted porosity of the screen by building it using two thin gauge metals that featured a proprietary pattern. Drawn to the geometry of the embossed 4LB sheet, the designers found the low relief pattern to perform comparably to a deeply stamped-style, which blended with other chosen patterns.

The screen’s pattern was articulated from varied perspectives to increases the transparency of facade applications. A dynamic quality for the facade was achieved by a slight twist through the entire structure, resulting from the geometry of the system to perform structurally. The team’s reason to use subtle twisting in the elevations was to overcome fabrication difficulties created by some geometric moves generated computationally.

The design models were heavily informed by material parameters and tested in Karamba for structural loading. Designed primarily in Rhino 5 and Grasshopper, the system components were turret-punched on a CNC, and folded on a press break to achieve a diamond shape. A seamless, continuous cell structure tabbing system was also milled so the shapes could be fastened with stainless bolts. The 3xLP team will exhibit their results at the Tex-Fab 5 event in Austin, Texas and as part of the SKIN competition, will continue working with RM as well as A.Zahner Company to fabricate the entire facade system.

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano

- Courtesy of © Nicholas Bruscia & Christopher Romano