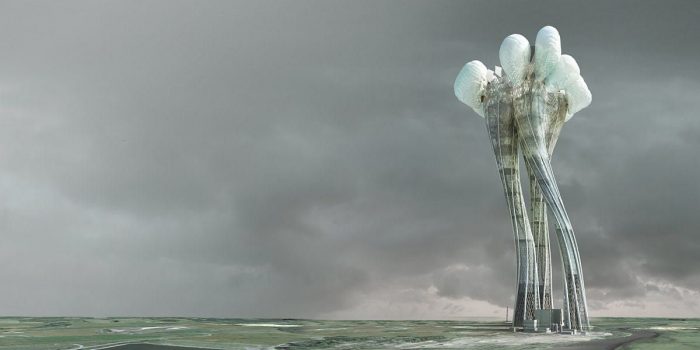

Coal Power Plant Mutation Bogdan Chipara

Again, one of our radically design posts, this Coal Power Plant Mutation by the Romanian architect, Bogdan Chipara, received one of the Honorable Mentions in eVolo competition 2012 and suggests a new approach towards fossil fuel power plants. Here is the project description from the architect:

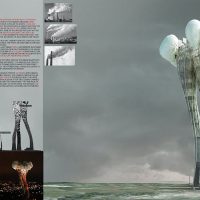

Today there are more than 50.000 active coal plants in the world and power demands are still rising. By 2030 fossil fuel power stations will account for 85% of the global energy market.

Power plants are no better than 50% efficient. That means that the power delivered as electricity is equal to the power released into the environment as heat. Fossil fuel fired power plants use large cooling chimneys to release this waste heat to the ambient atmosphere by the evaporation of water. The heat energy absorbed by water as it turns into vapour is later released into atmosphere whenever condensation occurs.

But the main reason concerning the coal plants is the flue gas exhaustion. By burning coal, the plant is producing carbon dioxide, nitrogen oxide and sulfur oxide. These pollutants are released into the environment through the thin chimneys known as flue-gas stacks. Later they react with the atmosphere creating sulfurous, nitric and sulfuric acids which fall as rain.

It is known that both flue gasses and water vapours released by power plants have a big impact on the environment.

2. Scenario

2. Scenario

Coal power plant mutation

We heavily depend on these energy producers and until alternative and green energy tech will evolve enough to support our demands, the coal power plants will be active.

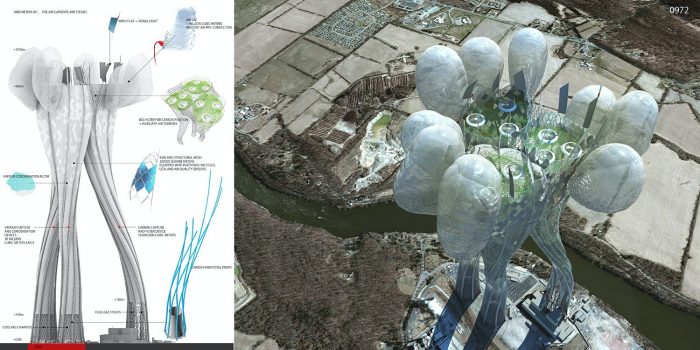

Instead of proposing new ways of producing green energy, the submitted project describes a mutation and a hybridization of the coal power plant.

To reduce the impact of the plants their exhaustion must be isolated and filtered before releasing them into the atmosphere. But to cope with such a large volume of gasses and vapours huge containers must be designed.

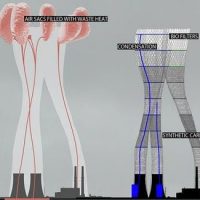

The carbon & vapoutr capture and filter devices placed on top of the chimneys measure 1000m height and have a volume of almost 10 million cubic meters. To sustain such a large structure, the design relies on the waste heat produced by the power plant. Some of the unused and light hot air will fill the, thus making the structure float 1000 meters in the air, where the air currents are steady.

The carbon & vapoutr capture and filter devices placed on top of the chimneys measure 1000m height and have a volume of almost 10 million cubic meters. To sustain such a large structure, the design relies on the waste heat produced by the power plant. Some of the unused and light hot air will fill the, thus making the structure float 1000 meters in the air, where the air currents are steady.

The structure is made out of multiple carbon-fiber steel props held together by a carbon-fiber steel mesh. The props are anchored in the existing foundation of the power plant.

The mesh is then covered by a light weight skin, a waterproof elastomer that isolates the gasses and vapours from the environment. The gasses and vapours do not mix, thus the risk of acid clouds formation is eliminated. The skin has an area of 300000 square meters and is equipped with photovoltaic cells leds and air quality monitoring sensors.

Power plants are placed near the cities, most of the urban inhabitants are not aware of their existence and impact. The main role of the leds that shine vertical patterns is to make people aware of their power demands and what these imply. The patterns will change according to the inner and outer air quality, monitored by sensors.

Inside these 1000 meter tubes various types of air filters with various densities are placed at different heights. The lower filters for co2 exhaustions use synthetic carbon fixation techniques while the upper ones are bio-filters. The filters placed on top of the cooling chimneys prevent the vapours from reaching the atmosphere. They are made of horizontal air pipes connected only to the exterior. The vapours condensate on them and the resulting water is gathered and distributed back at the base.

Architects: Bogdan Chipara

- Image: Bogdan Chipara

- Image: Bogdan Chipara

- Image: Bogdan Chipara

- Image: Bogdan Chipara

- Image: Bogdan Chipara

- Image: Bogdan Chipara

- Image: Bogdan Chipara

Courtesy of Bogdan Chipara