With precisions tools such as 3D printers, manufacturers like Nike are able to set motion to the boundaries of innovation and design. Nike has recently debuted their third football cleat called Nike Vapor HyperAgility Cleat. This models follows suite of Nike’s first launch of the 3D printed Nike Vapor Laser Talon cleat in their “40 Yard Dash project” last year.

Even more recently, in January, Nike launched their second shoe during the Nike Silver speed collection for the Super Bowl called the Nike Vapor Carbon 2014 Elite Cleat.

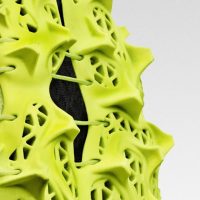

The Vapor HyperAgility cleat featuring 3d printed tri-stud cleat plates contour the bottom of the upper shoe’s Nike Flywire cables. These design elements enable optimum traction for decelerating and changing directions efficiently.

This is all part of Nike’s intention towards improving the players performance by continuously updating their products. In opposition to the former more traditional approach to footwear design and manufacturing, 3d printing technology has shown to be a superior method for designers to make adjustments and testing within hours instead of within months.

- Courtesy of © Nike Vapor

- Courtesy of © Nike Vapor

- Courtesy of © Nike Vapor

- Courtesy of © Nike Vapor

- Courtesy of © Nike Vapor

- Courtesy of © Nike Vapor

- Courtesy of © Nike Vapor

- Courtesy of © Nike Vapor