McLaren

The McLaren Production Centre is the second building designed by the firm Foster and Partners at McLaren’s rural site on the outskirts of London. The project runs from 2009-2011. The 34,500m2 facility is intended for the manufacture of a range of high performance road cars. It is located to the south-west of the existing McLaren Technology Centre.

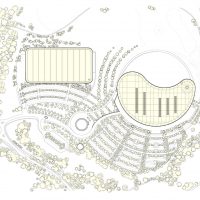

The two buildings, The McLaren Production Centre (MPC) and the existing McLaren Technology Centre (MTC) are connected by a subterranean walkway, lined with interactive exhibition spaces. The site is filled with green template so the building had to blend harmony with the existing architecture of the McLaren Technology Centre. To retain the building with the harmony of the available landscape, 180,000 m3 of soil was excavated and used to re-landscape the rest of the site. While building such structure on high water table land, the building was always under the issue of contamination. The resulting building is two story, with the buried portion being concrete, and the elements above the ground being steel. It was sensitively designed to integrate into the landscape to minimize its visual impact. The superstructure is designed using double primary beams and columns so that all the services, including air supply, power and data are concealed within the structural steel frame.

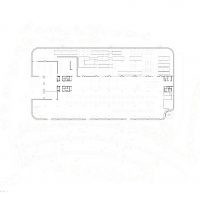

Key aspects to the design are its simplicity and the high level of repetition. A cross grid 18m, 21m, 21m, 21m and 18m was selected to optimize the working aisle widths beneath. These are then repeated on an 18m grid for 12 bays along the length of the building. Primary, secondary and tertiary beams were then optimized for these spans and repeated throughout the building. Although the bulk of the internal steel elements are standardized, the perimeter of the building and the entrance drums are expressed to match the visual appearance of the Technology Center. Elegantly detailed spiral stairs and viewing galleries were also added to enhance the visitors’ experience when entering from the Technology Center. In the majority of locations the steel work is left exposed. These areas received a high quality painted finish that matched the paint quality of any architectural finishes to give a very clean and consistent aesthetic to the space.

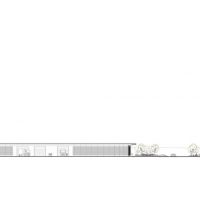

In the production line, the cars are assembled, painted and tested, and then pass through a rolling road and car wash, before leaving the building. Below this, is a basement level for storage and above is, a mezzanine floor with views over the production line. The expansion of the campus is a similarly discreet intervention in the landscape. Rising to just over 7 meters in height and embedded in the gentle incline of the site, the Production Center is sensitive to its rural setting and will not be visible from the nearby road.

In the production line, the cars are assembled, painted and tested, and then pass through a rolling road and car wash, before leaving the building. Below this, is a basement level for storage and above is, a mezzanine floor with views over the production line. The expansion of the campus is a similarly discreet intervention in the landscape. Rising to just over 7 meters in height and embedded in the gentle incline of the site, the Production Center is sensitive to its rural setting and will not be visible from the nearby road.

The new building is also designed to be sustainable where the Technology Center uses the lake for its cooling system, so the roof of the MPC supports this by collecting rainwater and implementing a low-energy system of displacement ventilation. Furthermore, the McLaren Production Center develops an approach to industrial architecture with staying in harmony of environment and sustainable development.

As per the Lord Foster, Founder and Chairman, Foster and Partners: “The McLaren Production Center is a further leap forward in the evolution of industrial buildings, both socially and in terms of working conditions and technologically in its flexibility and the sophistication of its services integration. The scale and grandeur of the main hall is a fitting complement to the purity of the McLaren cars, which will emerge from its production line. This project has been a wonderful opportunity to work once again with Ron Dennis, who is a great patron and friend. It is a testament to a fantastic team effort that this production center was achieved in just twelve months”.

Important Features:

- 3 jumbo jets can fit in the floor plan area

- 2,469 F1 cars could fit in the ground floor plan area

- If all the 218,000 ceramic tiles specified were laid end to end they would stretch from London to Reading

- If all the steel columns were stacked on top of each other they would reach a height of 895m, almost 3 times the

Project Information:

Architects: Foster and Partners

Location: Woking, Surrey, UK

Project Team: Norman Foster, David Nelson, Nigel Dancey, Iwan Jones, Dominik Hauser, Nina Linde, Chris Johnstone, Kathleen Mark, Nicholas Papas

Client: McLaren Group

Area: 34500 m2

Project Year: 2009-2011

Status: Built

Structural Engineer: Buro Happold

Quantity Surveyor: Gardiner & Thebold

M+E Engineer: PHA Consult

Landscape Architect: Terence O’Rourke

- photography by © McLaren

- photography by © McLaren

- photography by © Nigel Young

- photography by © Nigel Young

- photography by © Nigel Young

- photography by © Nigel Young

- photography by © Nigel Young

- photography by © Nigel Young

- photography by © Nigel Young

- photography by © Nigel Young

- photography by © Nigel Young

- photography by © Nigel Young

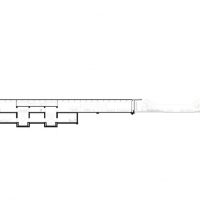

- plan

- Situation

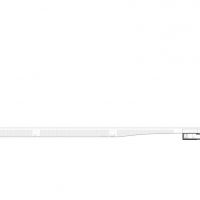

- Elevation

- Elevation

- Section

- Section