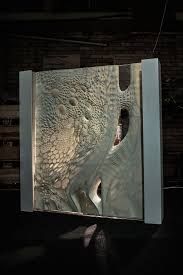

Currently displayed in Wates House, Bartlett School of Architecture, the piece is a part of an ongoing research in 3D printing in lieu of design of new material. The research not only highlights the importance of sophisticated manufacturing technology, but also of easy processing of high volume data flows in design.

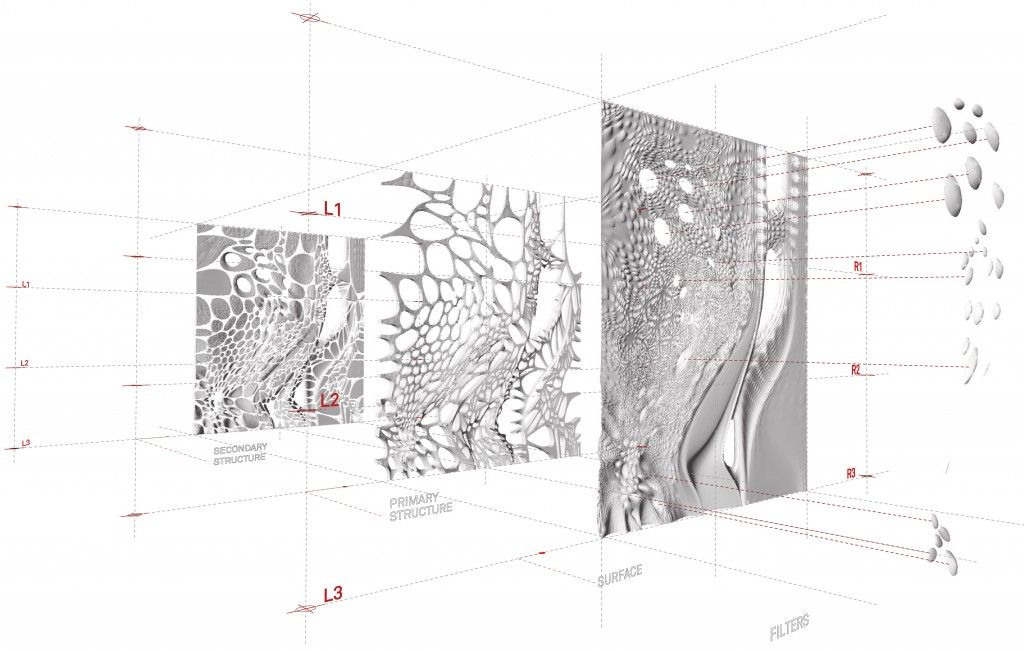

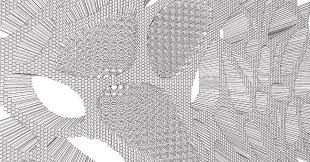

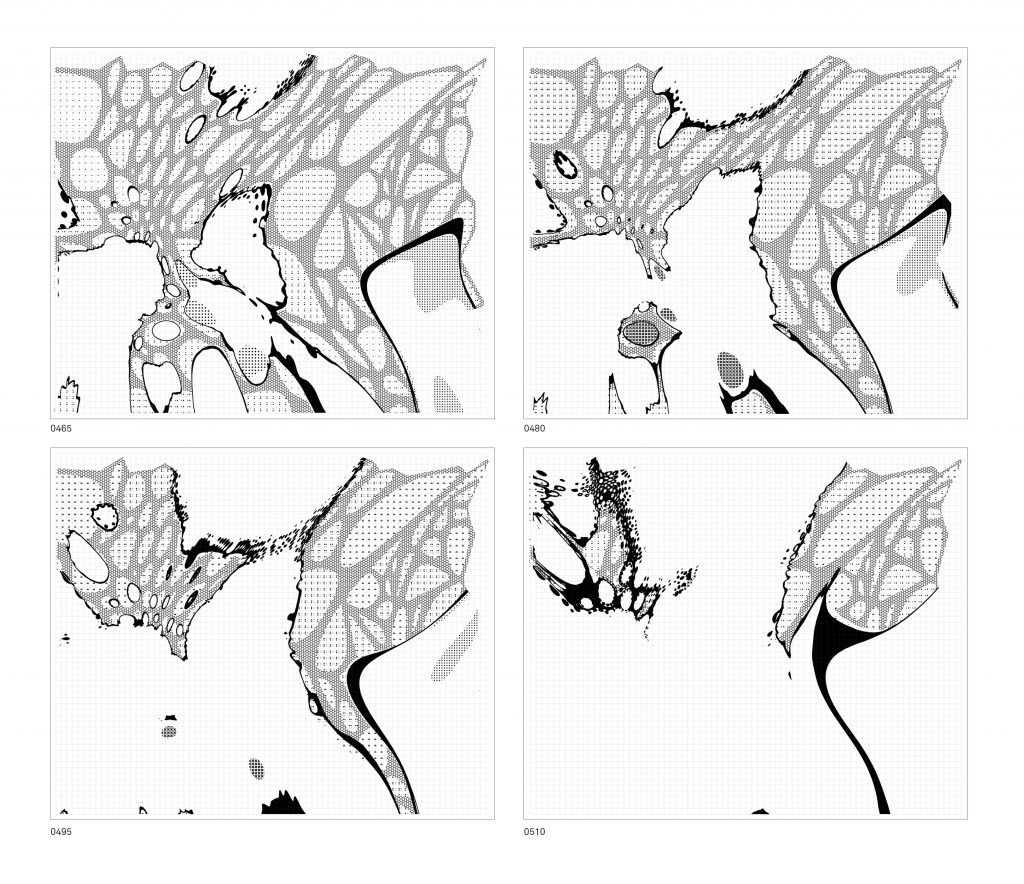

The material is made of sintered nylon with over 100 components with 10 different structural geometries yet is almost 1 mm thick. Created to respond to varying degrees of light transmission it the four basic layers are of primary structure, secondary structure, surface and filter which allow for the localized variation.

The entire prototype was built in a single laser sintering tank in over 4,700 120μm layers over 5 days hence its design exhibits a high range of control over properties ranging from optical and mechanical to thermal and electrical.

The installation is part of an article in a future issue of Architectural Design chronicling multiscale aspects of design.

Tags: 3D3D PrintingEducation

Ibrahim Abdelhady is an architect, academic, and media entrepreneur with over two decades of experience in architecture and digital publishing. He is the Founder and CEO of Arch2O.com, a leading platform in architectural media, renowned for showcasing innovative projects, student work, and critical discourse in design. Holding dual PhDs in Architecture, Dr. Abdelhady combines academic rigor with industry insight, shaping both future architects and architectural thought. He actively teaches, conducts research, and contributes to the global architecture community through his writing, lectures, and media ventures. His work bridges the gap between practice and academia, pushing the boundaries of how architecture is communicated in the digital age.