“The bamboo that bends is stronger than the oak that resists.” – Japanese Proverb

This may sound like nothing but a metaphorical motivational quote, yet it literally explains the notion of bamboo: its adaptability. Both as a plant and as a building material, bamboo has proved its ability to recreate itself into different forms according to changing conditions and environments. Adaptability is what -fluently- carried bamboo from a traditional to a contemporary building material!

Bathroom Pavillion Flor de Bambú by FabrikG – Photography by Daniela Fernández del Busto

Standing tall, this slender and firm plant can bend and lean into spectacular shapes. Bamboo can be used as an eco-friendly construction material, and furthermore, as a material to make the architects’ fantasies of natural curved forms come true! However, there are several factors to take into consideration before bending bamboo, including its type and strength, and, accordingly, the bending method.

Types of Bamboo

Bamboo falls under a subfamily called “Bambusoideae”, which belongs to the grass family “Poaceae”. This subfamily comprises both woody and herbaceous bamboos, making 1,718 bamboo species. Bambusoideae can be divided into three main subdivisions:

- Temperate woody bamboos

- Tropical woody bamboos

- Herbaceous bamboos

However, because of their varying characteristics, not all bamboo types can be used in construction. The best bamboos to be used as a building material are:

- Genus Guadua: because of its superior size and strength.

- Genus Dendrocalamus (Solid Bamboo): known for its hardness.

- Genus Bambusa: used for building walls or scaffolding because of its thick diameter.

- Genus Phyllostachys: makes one of the strongest timber bamboos.

- Genus Chusquea: known for its strength and is tolerant to extremely cold climates.

How Strong is Bamboo?

Bamboo is stronger than usually assumed. Compared to the conventional building materials known for their strength, bamboo is competitive! It is three times stronger than timber. Moreover, compared to steel, bamboo provides more tensile strength, meaning it can stretch and withstand more tension than steel before breaking. When it comes to concrete, one of the strongest materials in the construction field, bamboo withstands compression better.

Nocenco Cafe – Image is Courtesy of Trieu Chien

These traits added to the lower cost and positive environmental impacts caused by planting bamboo comprise a win-win situation!

Additionally, the dense fibers in bamboo canes make it extremely flexible, allowing it to bend into different shapes and, more importantly, to stand still during earthquakes. Bamboo forests and buildings made of bamboo make safe shelters during such catastrophes.

How to Bend Bamboo?

Courtesy of BambooU

Architects and artists have been getting creative with the potential of bamboo, creating curved structures, furniture, and sculpture pieces. Bamboo grows straight and sturdy, and to curve it, one must follow certain techniques, including heating, steaming, and kerf bending.

Methods to Bend Bamboo

Courtesy of BambooU

-

Finding Naturally Curved Bamboo

The shortest solution is going for bamboo poles that grew naturally into curves, but it is not a convenient one—naturally, curved bamboo poles are rare, as bamboo is trained to grow vertically to avoid interweaving and produce uniform bamboo poles. It would also be difficult to find the exact desired curve if you are looking for one.

-

Growing Curved Bamboo

Courtesy of Better Bamboo Buildings

Find a bamboo clump with young poles and curve them over time, using car tires or ropes to tension them into the desired curve to be harvested and processed.

-

Green Drying

Harvest a green bamboo pole, and dry it in a mold that has the desired curve. Following this method, once the bamboo is dry, it cannot be curved furthermore. However, there are other techniques to curve dry bamboo.

-

Soaking or Steaming

Just as wood, bamboo is bendable when soaked or steamed—the moisture softens the fibers in the bamboo and makes it more flexible. However, this method works best with small diameter and less dense bamboo types, and will not be convenient with stronger and thicker bamboo types.

-

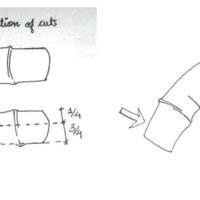

Heating Bamboo

This bending method is more advanced than the previous ones and requires more skilled craftsmen. Firstly, bamboo poles should be hollowed using a piece of rebar to break its internal nodes.

After that, holes should be drilled into the bamboo to allow the vapor to escape during the heating process. By then, bamboo is ready to be heated—the heat should be applied in the direction of bamboo growth.

Courtesy of Guadua bamboo

After checking the bamboo for flexibility, the hollow bamboo poles should be filled with fine sand to stabilize and strengthen the bamboo. This makes the bamboo ready to be bent into the desired shape. The bending process comprises three steps that are repeated until the wanted curve is achieved; torching, bending, and dampening.

-

Applying Heat and Pressure

This is another method to bend dry bamboo, where the bamboo nodes are heated, then two or more bamboo poles are bolt and tied together before being bent to create a stronger and more durable curve.

-

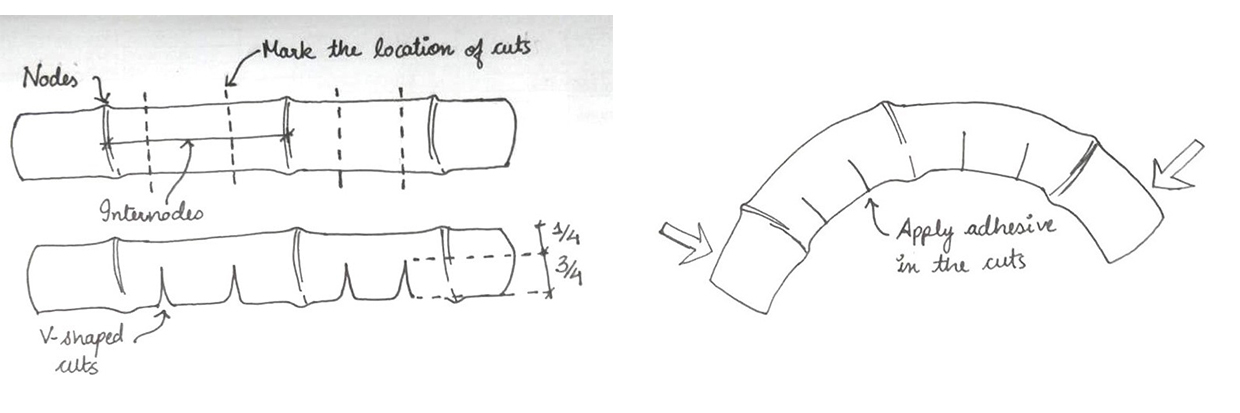

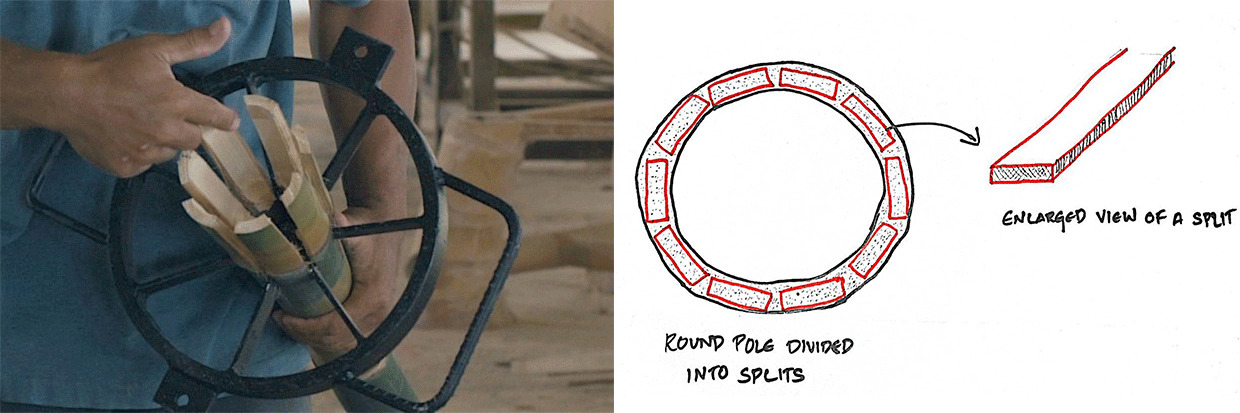

Splitting Bamboo Poles

Courtesy of BambooU

In this bending method, v-shaped cuts are made into the bamboo poles, preferably near the bamboo nodes for better aesthetics. The size of the v-cut depends on the desired curve. It should be noted that this method weakens the bamboo pole—to make up for this, two or more bamboo poles should be tied together to provide better strength.

- Bathroom Pavillion Flor de Bambú by FabrikG – Photography by Daniela Fernández del Busto

- Nocenco Cafe – Image is Courtesy of Trieu Chien

- Ulaman Retreat by Inspiral Architecture and Design Studios – Photography by Mati Allendes

- Courtesy of BambooU

- Courtesy of Better Bamboo Buildings

- Courtesy of Guadua bamboo

- Courtesy of BambooU

- © nARCHITECTS

- Courtesy of BambooU