Digital fabrication (DF) developed rapidly over several years and it came with the promise of changing the face of architecture, and only then did its progress come to a halt. Although it seems that digital fabrication had gone under the radar, it is still the subject of many studies and the source of inspiration for several architects and universities. It is important to know that any manufacturing process aided, or completely controlled, by a computer is considered a form of digital fabrication. In this ever-growing field, new technologies are being developed at a substantial pace, but there are three major methods of DF: Additive manufacturing, subtractive manufacturing, and robotic manipulation.

Digital fabrication is a form of computer-aided design that encompasses endless possibilities within, and the previously mentioned methods are ways in which digital fabrication can be integrated into a design. The impact of digital fabrication on the architectural scene can’t be underestimated, and we are going to provide you with this overview of digital fabrication and its latest trends and projects.

1. Additive Manufacturing (3D printing)

Additive manufacturing is a technology that emerged in the 1980s using stereolithography (SLA) to layer material to create a certain shape. The process is basically shooting an ultraviolet laser beam into a mass of photopolymer, which then hardens the photopolymer into the plastic. Additive manufacturing isn’t only limited to plastic, since now it has expanded to include clay, metals, glass, nanocomposites, and unexpectedly, human flesh. (Did you know that we can print out human organs?)

Here we are going to look at one of the projects that took additive manufacturing to a completely new level, exhibiting the unlimited potential of digital fabrication.

VULCAN | Laboratory for Creative Design and Beijing Design Week

This experimental, 3D-printed pavilion was hailed as the masterpiece of the 2015 Laboratory of Creative Design and Beijing Design Week and also the World’s Largest 3D-Printed Architectural Pavilion Vulcan. It stood mightily as a structure that shows off the power of digital fabrication. Looking almost like a spacecraft, this 3D-printed structure is spread across 8.08m in length and stands at 2.88m.

Conceptualized and brought to life by architects Yu Lei and Xu Feng from Laboratory for Creative Design (LCD), Beijing, Vulcan consists of numerous 3D printed modules assembled to look like an erupting volcano (thus the name). The design is heavily inspired by silkworms, with a tripodal design with silky lines running across it. The polygonal facets were 3D printed by a team consisting of 15 individuals using 20 large 3D printers. It took only 12 days to finish the design and to assemble a total of 1086 3D-printed pieces to form this masterpiece.

2. Subtractive Manufacturing (Machining)

Subtractive manufacturing is a method of digital fabrication in which 3D objects are constructed using machines (such as CNC milling) that cut away at the material until the desired shape is reached. Model-making techniques are also considered subtractive manufacturing, such as IKEA Lab’s Growroom that we are going to explore shortly. Initially, the material comes in the form of a solid block, and then the robotic arms employ laser cutting and hot wire to achieve the most intricate of designs.

Growroom | IKEA Lab

Developed by the IKEA innovation lab Space10, together with architects Mads-Ulrik Husum and Sine Lindholm, Growroom is a DIY spherical garden structure designed with the intent of allowing people to grow their own food within their residences. The design combines sustainability with digital manufacturing to bring the urban population closer to nature; to allow them room to breathe and to participate in preserving the environment through making conscious and eco-friendly choices.

The design of Growroom is made available online and it requires only 17 sheets of plywood, metal screws, and a CNC milling machine. Following the guidelines provided by the IKEA Lab, you’d be able to assemble your own Growroom easily together and witness, firsthand, the magic of digital fabrication.

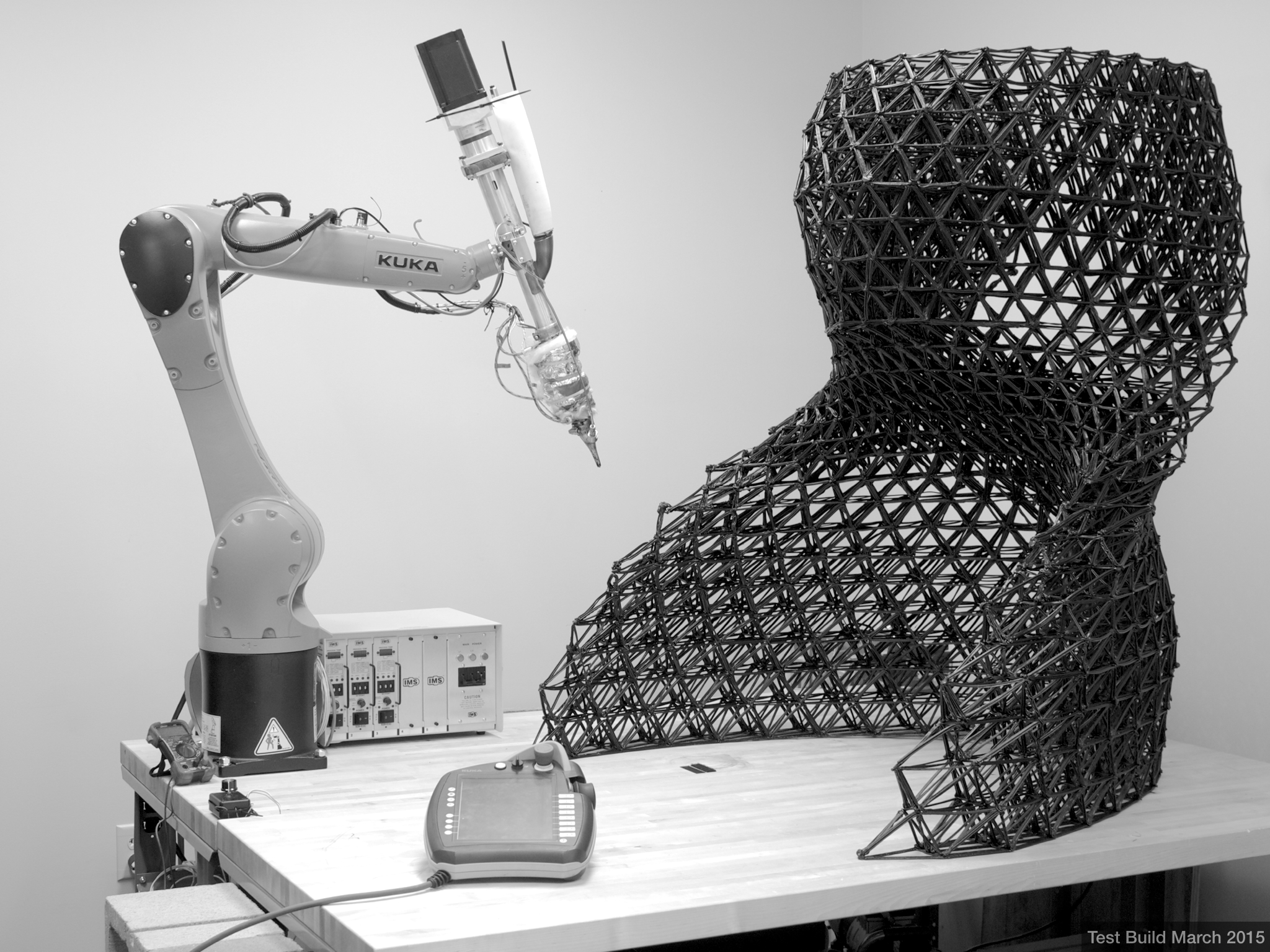

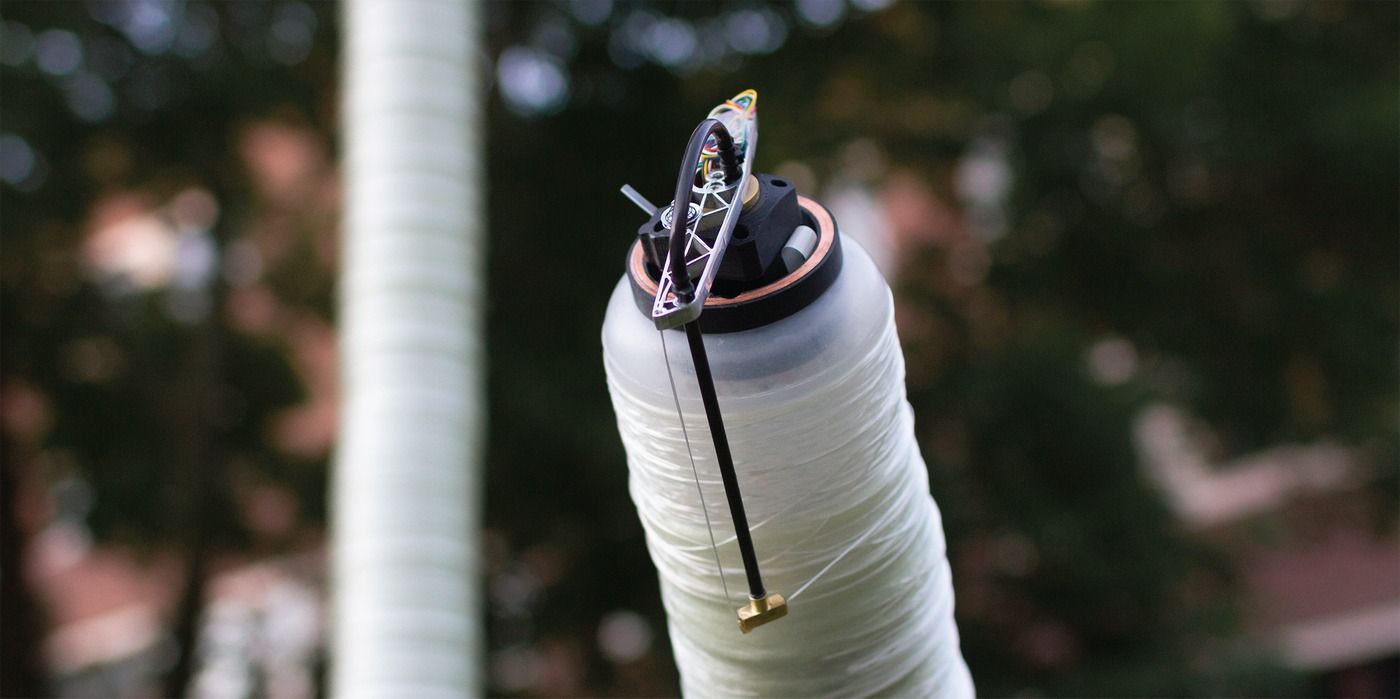

3. Robotic manipulation

Robotic manipulation is an umbrella term that includes any other form of digital manufacturing such as folding, weaving, and bending. The wonder of robotic manipulation is the fact that if we utilized the right tools, then robots can be used to complete a variety of tasks, and since robots are capable of far many more things than man is, then in unison with the creativity of designers and architects, the possibilities will be endless.

Neri Oxman Design X MIT Team | Firebots

An autonomous digital fabrication platform was designed by the MIT-based Mediated Matter Group to quickly build architecture in the case of, or during, disasters. The small robots work together as a group of fiberglass filament and they have the appearance of high-strength tubular structures. These bots were born from the vision that they can work under extreme conditions in natural disaster-prone zones.

The team consists of 16 robots that are controlled by a design system, all working together to enable a speedy construction of any architectural design. They were developed inside a studio and then deployed to autonomously create the 15 ft tall structures that they are. The Firebots are designed specifically to enable designers and architects to use digital fabrication for large-scale structures. The bots are created with the intent of creating, or rather weaving, a structure on spot, no matter how harsh the surrounding circumstances could be.

Digital fabrication: the next steps

The brilliance of digital manufacturing shows in its ability to help architects and designers achieve really complex structures with minimal cost and effort. Although digital manufacturing is advancing slowly through the architectural scene, its potential is unquestionable. The long-awaited revolution in architecture will definitely be carried by digital manufacturing as it will allow the most fantastical and complex visions to be brought to life with ease. Through unleashing the imagination of designers and architects while providing them with the extraordinary facilities of digital fabrication, what we know as architecture will be reshaped entirely as nothing will stand in the way of achieving the most revolutionary visions.