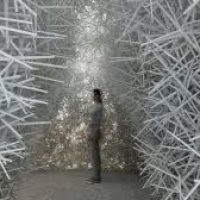

Aggregate Pavilion

The Institute of Computational Design, Stuttgart recently showcased the Aggregate Pavilion, which is part of a research that aims to explore the possibility of building structures using a ‘designed granular system’, a technique that employs synthetic particles that can be individually programed to create structures that do not require any kind of additional formwork.

The designers of the pavilion, Karola Dierichs and professor Achim Mendes, after a yearlong period of extensive research, using scale models and full sized prototypes, came up with a format that included three different kinds of recycled plastic granules as the basic buildings blocks for the pavilion. The injection moulded plastic granules have either six of four slender arms with the third kind of particle also having six arms but lager in scale that the other two. The tendency of these particles gripping and binding to each other makes them perfectly suited for constructing vertical structures.

The towers of the pavilion were made using a suspended robot using cables tied to trees around the site of construction. The robot was calibrated to drop a payload of around 10 kilograms to the precision of just a few centimeters.

30000 particles were layered together in order to create the towers of the pavilion and all this was done in a matter of a few hours. The project successfully demonstrated the feasibly of this method for constructing structures that require swift erection and need to adapt easily to different requirements. The concept was furthermore proved fesable during its exhibition period when the pavilion was dismantled and reconfigured several times.

The Aggregate pavilion demonstrates a very novel substitute to current construction techniques, as it does not require any kind of binding material or formwork and is also a more time saving and effective method of construction as compared to the traditional structures made using concrete and steel.

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart

- Courtesy of ICD, University of Stuttgart