Spatial Curves

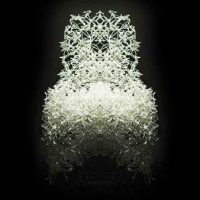

Team CurVoxels have developed an experimental technique for seamless robotic 3D printing of complex curvilinear structures. The project titled Spatial Curves was completed at Research Cluster 4 of The Bartlett School of Architecture, UCL by team CurVoxels – Hyunchul Kwon, Amreen Kaleel, and Xiaolin Li. Research Cluster 4, directed by Manuel Jiménez García and Gilles Retsin, investigates the use of robots for large-scale 3D printing of Architecture. RC4 has produced a number of 3D printing methods in different materials, which are always tested on the scale of furniture and architectural elements. Students have produced a range of objects such as 3D-printed staircases, columns, tables, and chairs in concrete, timber, and plastics. CurVoxels used the idea of the “cantilevering chair” or “S-Shaped Chair” as a starting point to investigate and test the printing process. The first cantilever chair was designed by Mart Stam at the Bauhaus, made of steel bicycle tubes. This chair was then further developed by Marcel Breuer. With the introduction of plastic injection molding, Danish designer Hans Christiansen Dansk builds the first plastic S-shaped chair in 1960. Roughly at the same time, Verner Panton develops his own iconic version of the cantilever chair, which went into production in 1965. CurVoxels questions how the cantilever chair would develop when confronted with a new fabrication technique like robotic 3D printing. The team developed a custom-made extruder that can extrude 4-6mm thick wires in the air, avoiding layered printing. The industrial robot drags plastic from the extruder in the air where it is cooled down. This method allows to print faster, use less material, and achieve filigree like structures with a high degree of detail. CurVoxels developed a digital technique that uses a combinatorics algorithm to aggregate a single curvilinear element into a continuous, kilometers-long extrusion. The printed objects are extruded in a single, continuous, and seamless plastic line, which allows the robot to never interrupt the printing process. This computational method is synthesized in a small App, which allows designers or users to customize their chairs and generate toolpaths for the robot.

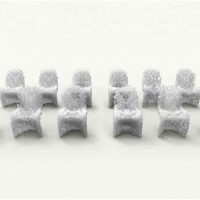

Initially, a model of the Panton chair is voxelized, a process of dividing an object into 3-dimensional pixels. These voxels are translated into a basic spatial curve, which can adopt different orientations, generating an overall pattern throughout the geometry. A printable spatial curve was developed as a building block for a combinatorial system that generates a single continuous spatial curve to enable the industrial robot and customized extruder to print the space frame structure without stopping. The size of the voxels changes depending on the amount of stress in the chair, distributing different material densities. The voxelized Panton chair is more volumetric than the surface-like original. The system works by calculating tangents and points of connectivity to other voxels from the curve of a single voxel. Each discrete voxel unit has 24 possible rotations, which enables it to generate a differentiated, heterogeneous pattern. Converting a curve into a discrete voxel unit enables quick evaluation of printability with a high level of control over patterns that can be modified until an optimal design is reached.

When the voxels are very small, the spatial curve effectively becomes no more than a line. What appears as two different formal syntaxes, curvilinear versus linear, is actually the product of a single spatial curve on different scales. Through the first simulations, twelve different design issues were examined, of which toolpath continuity, patterns resulting from combinatorics, printability, and density were the most important. CurVoxels uses this method to introduce different material densities in the structure, but at the same time, this differentiated voxel also introduces multi-scalar patterns with different levels of hierarchy. In further architecture-scale speculations, this property can be used as a space-generating device, understanding large-scale hollow spaces as large voxels, and the surrounding structure as dense material with a small voxel. CurVoxels won the Golden Track Award for the best project of the year in March Architectural Design at the Bartlett School of Architecture, UCL. Spatial Curves project was presented at The Bartlett’s B-Pro Show 2015 graduation exhibition in London, UK, and Synthetic 2015 Exhibition in Le Mans, France.

CuVoxels | SPATIAL CURVES | 2014-2015

Project credits:

Team CurVoxels: Hyunchul Kwon, Amreen Kaleel, Xiaolin Li.

Tutors: Manuel Jiménez García, Gilles Retsin, Vicente Soler Senent, Research Cluster 4 at UCL the Bartlett School of Architecture.

Photo Credits: Team CurVoxels, Sin Bozkurt