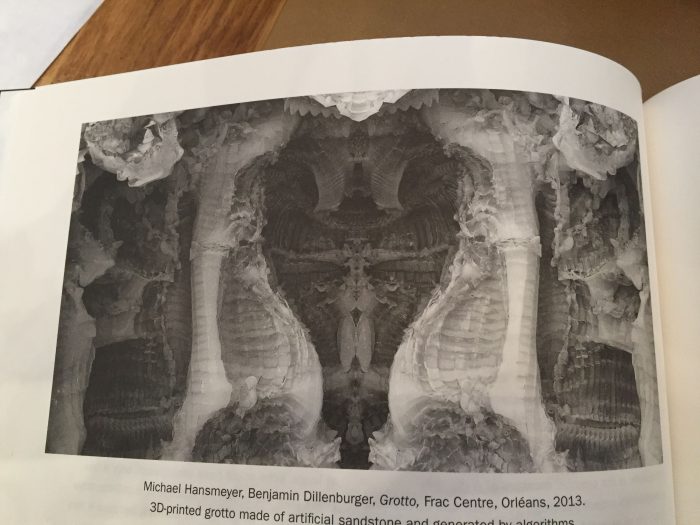

Often when we picture 3D printing we imagine it at the scale of a prototype. However, Michael Hansmeyer and Dylan Dillenburger took all scale off the table when they built their project called “Digital Grotesque” from the ground up.

This full-scale 3D printed room was “materialized by custom designed algorithms. Using computer based data input [and] a geometric mesh of 260 million specified micro-details” into one monumental feat of digitally fabricated architecture.

A sandstone 3D printer uses sand as its support material instead of the commonly used wax, or scaffolding found in other types of 3D printing machines.

This makes for the ability to manufacture projects in a single piece at a large scale, recyclability and easy cleanup of the support material. This Method of printing recently emerged, and now in the hands of great forward-thinking individuals like Michael Hansmeyer and Dylan Dillenburger seemingly conceptual and unbuildable masterpieces are being 3D printed.

By Ariela Lenetsky

- courtesy of Michael Hansmeyer and Dylan Dillenburger

- courtesy of Michael Hansmeyer and Dylan Dillenburger

- courtesy of Michael Hansmeyer and Dylan Dillenburger

- courtesy of Michael Hansmeyer and Dylan Dillenburger

Courtesy of Michael Hansmeyer and Dylan Dillenburger