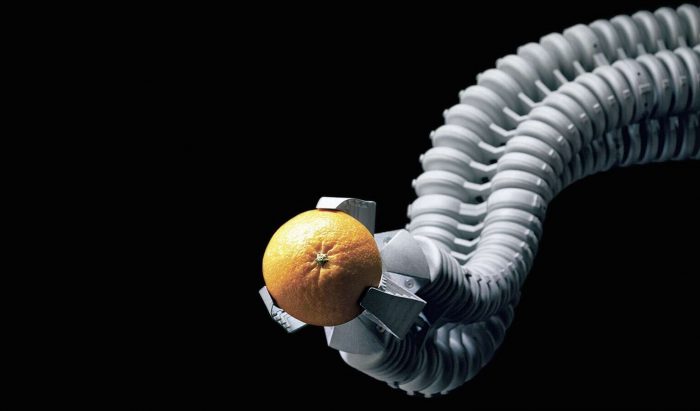

The elephant’s trunk has influenced a design of a bionic arm. Festo is designing a bionic arm such as this is an attempt to revolutionize usage technology for human-machine assistance. Safety is what Festo is concerned about with because the bionic handling assistant, which is a direct connection between the user and the machine, doesn’t finding the middle ground in safety.

Such as if there were an occurrence where there is an accident with a human, the artificial hydraulic arm yields instantly. The controlled safety reaction operates without altering its preferred overall performance. Once the bionic arm experiences a collision it continues its operation after resolving the conflict unlike more machines. This process is characterized by a mass-payload ratio, which is a smooth operating action with several degrees of choice and proficient use of assets.

Such as if there were an occurrence where there is an accident with a human, the artificial hydraulic arm yields instantly. The controlled safety reaction operates without altering its preferred overall performance. Once the bionic arm experiences a collision it continues its operation after resolving the conflict unlike more machines. This process is characterized by a mass-payload ratio, which is a smooth operating action with several degrees of choice and proficient use of assets.

3d printed parts are what this bionic arm is made up of. There are three elements that the handling system consists of for spatial movement. It is one system with a hand axis that has a ball joint and a gripper with adaptive fingers.

3d printed parts are what this bionic arm is made up of. There are three elements that the handling system consists of for spatial movement. It is one system with a hand axis that has a ball joint and a gripper with adaptive fingers.

This year, the Engineers at Festo have used a method called “global babbling”, which is a process that mimics the way babies learn how to grab things by repetitively reaching, by trial and error it will let the users figure out what needs to be moved. With this technique the bionic arm can be physically forced into various positions and learn to implement them on command.

This year, the Engineers at Festo have used a method called “global babbling”, which is a process that mimics the way babies learn how to grab things by repetitively reaching, by trial and error it will let the users figure out what needs to be moved. With this technique the bionic arm can be physically forced into various positions and learn to implement them on command.

This allows the arm to repeat actions such as plucking hazelnuts to switching light bulbs. The bionic arm remembers what happens to the trunks arrangement when changes are made to the stress in the thin pneumatic tubes, which are the artificial muscles. When these changes are made the bionic arm remembers them just like a babies muscle memory.

This allows the arm to repeat actions such as plucking hazelnuts to switching light bulbs. The bionic arm remembers what happens to the trunks arrangement when changes are made to the stress in the thin pneumatic tubes, which are the artificial muscles. When these changes are made the bionic arm remembers them just like a babies muscle memory.

- Courtesy of © Festo

- Courtesy of © Festo

- Courtesy of © Festo

- Courtesy of © Festo

- Courtesy of © Festo

- Courtesy of © Festo