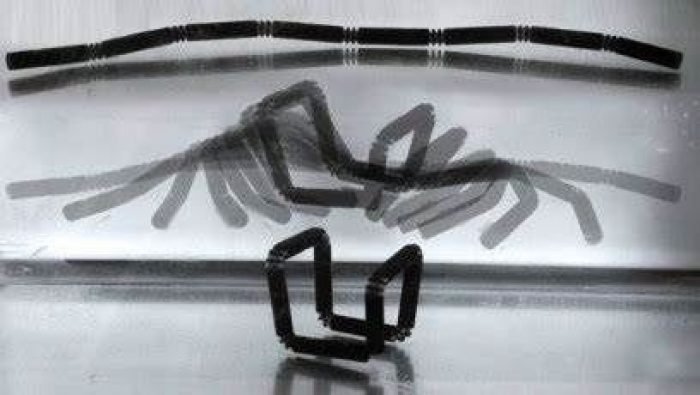

The 3D printing space is bringing to the table its fourth dimension – time. Long associated with robotics, 4D printing is now going beyond this, using more than programming: it’s become a physical and chemical phenomenon, blending with technology and CAD software. Instead of using mechanical parts, it uses materials with a particular behavior. Used for the first time in 2013 within the collaboration of Stratasys’ Education, R&D departments, and MIT’s Self-Assembly Lab, led by Skylar Tibbits, the research focused on creating a developing self-assembly technology for large scale constructions. The work of Tibbits focuses on creating material from a rigid, inert polymer, and a softer component. They are blended into a component that transforms when in contact with water or heat – basically, a 1D strand becomes a 3D object. It can become 150 percent bigger than its original size, and it is flexible, manageable to be bent. The team created both self-folding strands, and self-folding surface cubes, but various other geometries are possible by using the same joints. This is highly useful in the architectural approach. Professor Achim Menges, head of the Institute for Computational Design at Stuttgart University, states: “First you use the new technology to build objects in the traditional way, as demonstrated by the example from China, where they are building conventional houses with 3-D printers. Designs and constructions that are genuinely specific to the new process are not created until the second step. This means that 3D printing will make geometric complexity in building construction possible without much additional effort or expense. This knowledge in turn informs the design process. Just as developments in software changed the aesthetic of architecture, so could 3-D printing.” Therefore, due to multiple layering, we will have the possibility of creating very complex building components with gradient characteristics. Components could be soft on one end and hard on the other due to different printing materials being used in the course of the 4d printing with a multi-material printer.” We are thus witnessing components that can change shape, working on the same principle.

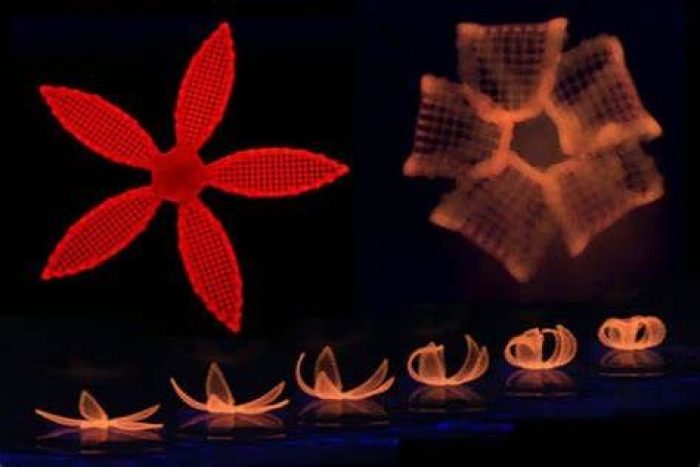

4D Printing: Many other similar experiments have come to life, such as the one conducted at Harvard University with a similar method, in which objects respond to environmental triggers such as plants. Through the use of hydrogel-cellulose fibril ink, a gel formed of cellulose microfibers derived from wood, the microstructures in plants are used, especially those that allow fluctuation in shape such as term nasty, which is movement in response to temperature shifts, and mimetic polymorphism, which is the change of shape in order to match adjacent foliage. The swelling behaviors thus developed are imitating the natural microstructure tissue of plants, by aligning the cellulose fibers in order for their directional swelling are dependent on each other, or anisotropic (anisotropy is a property of cellulosic structures that present grain and have various behaviors on regards to the direction). While materials such as plywood are treated to eliminate anisotropy, the entire research done at Harvard revolves around this property, using it to direct the material in a certain direction. When sunk into the water, the 4d „flowers” curl up in a dictated direction towards the center. Another study, done by the Colorado – Singapore group, conducted by H. Jerry Qi, uses heat to reshape polymers incorporated through an entire print. This time, thin plates are infused with glass-like polymer fibers, which have shape memory. „These fibers exhibit the shape-memory effect, which is used to create the “active” part of the composites. The PACs are then thermomechanically programmed to assume three-dimensional configurations such as bent, coiled, and twisted strips folded shapes, or complex, contoured shapes with nonuniform curvatures”. “The shape change is controlled through the design of ordered material structures or inhomogeneities at the micrometer scale. Inhomogeneities are widely used in mechanical engineering to enhance material performance. The inclusion of inhomogeneities is typically done randomly, as it is very difficult to control precisely where they can be placed. However, with 3D printing, the desired properties (which can be predicted by theory) can be achieved, which gives us the ability to control the performance of the material.” But all these experiments are not only this – they can be incorporated not only into architecture, but into product design, car or airplane producing, fashion, or electronics. We can only invite you to step into the future with us, with materials and products so smart they create themselves.